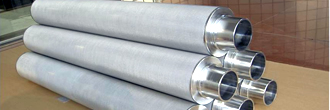

Cylindrical Filters

Filter cylinders

mainly serve in catalyst recovery, filtration of polyester, oil products, chemicals and pharmaceutics processing.

Filter cylinders

mainly serve in catalyst recovery, filtration of polyester, oil products, chemicals and pharmaceutics processing.

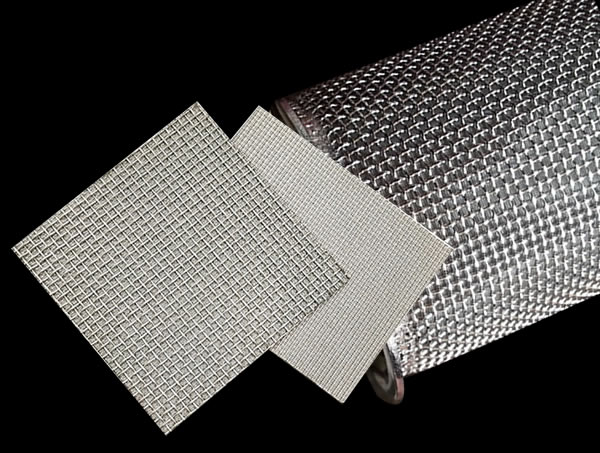

Filter media for filter cylinders: Woven wire mesh, Sintered Metal Powder and Multi-layer Sintered Mesh. Mostly processed from sheet mesh metal rigid panels into pipe forms. Simple structure without supporting layer.

Popular Product

Cylindrical filters, stainless steel cartridge, material SS316L, micron rating: 74 micron, 50 micron, 30 micron, 10 micron, 5micron, 3micron, 2micron and more..

Woven Wire Mesh Cylindrical Filter Cartridge

Stainless steel mesh filters for filter housings

Filtration rating:

25 microns.

Metal Sintered Powder Filter Cylinder

Metal Powder Filter Cylinder cartridges are design for a variety of applications

including: corrosive liquid and gases,cryogenic fluid, high viscosity solutions, steaming, high temperature liquids and gases and catalyst recovery.

Features and Benefits:

Features and Benefits:

High corrosion resistance;

Sintered metal construction;

Backwashable for re-use and maximum economy;

Multiple end configurations and gasket/o-rings to fit most all vessels.

Specifications:

Media: stainless steel

End caps: stainless steel

Gaskets/o-rings options: EPDM,Buna-N,Teflon,encapsulated Viton(O-Rings only)

Micron ratings: 0.5,2,5,10,15,35um

End configuration:

Double open End

226/Flat Single Open End

222/Flat Single Open End

3/4 inch Male NPT

1 inch Male NPT

Working Condition :

Max. operating temp:700 F(371 C)

Max. differential pressure

250 psid(17.4 bar) forward

50 psid(3.5 bar) reverse

Sintered Mesh Sheet Fabricated Cylindrical Filter Elements

This is type of Cylindrical Filter Elements have long service life. Sintered mesh filter pipes can withstand harsh work conditions and high temperature..

Five-Layer Sintered Wire Cloth consists of five layers of stainless steel wire mesh, which are sintered together

in vacuum.

Cylindrical Filter Elements made of Five-Layer Sintered Wire Cloth as filter medium, which have many advantages:

1) boast of fine micron filtering,

2) good permeability,

3) high strength,

4) easy to clean,

5) good corrosion resistance,

6) durable at work

7) no immigration of materials.

Sizes: Any outline size is available at customer's requirement.

Specifications:

| Filtering level | Filtering Precision ( μm) |

Maximum Aperture ( μm) |

Permeability m3/h.m2.kpa | Thickness mm | Compressive strength Mpa/cm2 |

| S9 | 0.2 | 2.5 | 1.5 | 3 | 3.0 |

| S8 | 0.5 | 4 | 3 | 3 | 3.0 |

| S7 | 1.0 | 6 | 5 | 3 | 3.0 |

| S6 | 2.5 | 10 | 15 | 3 | 3.0 |

| S5 | 5 | 15 | 40 | 3 | 3.0 |

| 8 | 20 | 80 | 3 | 3.0 | |

| S4 | 10 | 30 | 120 | 3 | 3.0 |

| S3 | 20 | 60 | 250 | 3 | 3.0 |

| S2 | 30 | 100 | 500 | 3 | 3.0 |

| S1 | 50 | 160 | 800 | 3 | 3.0 |

| Available Temperature: ≤600°C; Material: SUS304, 304L, 316, 316L, 317L, 410L, 430L, 434L. | |||||

How to Choose Cylindrical Filter Elements

Choose between Sintered Powder Cylindrical Filters and Sintered Mesh Cylinder Filters - Aadvantages and disadvantages

Both sintered powder cylindrical filter elements and sintered wire mesh filter cylinders have their unique advantages and drawbacks based on their construction and material properties, listed as below for references:

Sintered Powder Cylindrical Filter Element:

Advantages:

Versatility: The porosity and particle size can be well controlled during the manufacturing process, allowing for a wide range of filtration grades.

Homogeneity: Offers a more uniform structure, which can lead to consistent filtration performance throughout the element.

High Dirt Holding Capacity: Due to its porous nature and depth filtration mechanism.

Reusability: Can be cleaned and reused, especially the metallic variants.

Thermal Stability: Metal powder sintered filters can operate at higher temperatures.

Chemical Resistance: Depending on the base metal or alloy used, they can offer good resistance to many chemicals.

Disadvantages:

Mechanical Strength: While they have decent mechanical strength, they might not be as robust as wire mesh filters under high differential pressures.

Potential for Media Migration: In some cases, especially if not properly sintered, there's a possibility of media shedding or migration.

Sintered Wire Mesh Cylindrical Filter Element:

Advantages:

High Mechanical Strength: The wire mesh structure provides excellent resistance to pressure differentials and mechanical stress.

Defined Pore Structure: The layering of wire meshes allows for precise control over the filtration grade.

High Thermal Stability: Like sintered powder, metal wire mesh filters can operate at high temperatures.

Easy Cleaning: The structured layers and channels make backwashing and cleaning effective.

Versatility: By combining different mesh layers, it's possible to create multi-functional filters that combine fine filtration with support layers.

Long Lifespan: Due to their robust construction.

Disadvantages:

Cost: Generally, sintered wire mesh filters might be more expensive than sintered powder filters due to the complexity in layering and manufacturing.

Dirt Holding Capacity: While they can capture a significant amount of contaminants, they might not hold as much dirt in comparison to depth filters like sintered powder.

The choice between sintered powder cylindrical filter elements and sintered wire mesh cylinder filter elements depends on the specific requirements of the application. Consider factors like required filtration precision, operating pressure, mechanical stresses, cleaning frequency, and budget when making a decision.

Choose between Wire Mesh Pleated Cylinder Filter Element and Sintered Mesh Pleated Cylinder Filter Element - Advantages and disadvantages

Both wire mesh pleated filter cylinder and sintered mesh pleated filter cylinder are used in various industries for filtration purposes. Their pleated design increases the surface area, thereby enhancing the dirt holding capacity and extending the life of the filter. Following is a comparison of their features, advantages, and disadvantages:

Wire Mesh Pleated Cylindrical Filter Element:

Features:

Made by folding a wire mesh (or multiple layers of wire mesh) into pleats.

Typically offers surface filtration.

Advantages:

Cost-Effective: Generally less expensive to produce than sintered mesh filters.

Flexibility in Design: Different mesh sizes can be layered to achieve the desired filtration grade.

Easy Cleaning: Dirt and particles often get captured on the surface, making them easier to clean or backwash.

High Flow Rates: Due to the increased surface area from pleating.

Disadvantages:

Mechanical Strength: While they have decent strength, they might deform under high differential pressures or if subjected to mechanical stresses.

Less Consistent Pore Size: The pore size might not be as consistent as in sintered mesh, leading to variable filtration efficiency.

Potential for Media Bypass: Over time or under certain conditions, gaps can form between the layers, allowing for bypass of unfiltered media.

Sintered Mesh Pleated Filter Cylinder:

Features:

Made by pleating a sintered wire mesh, which is a layered mesh fused together through a sintering process.

Provides depth filtration, enhancing dirt holding capacity.

Advantages:

Superior Mechanical Strength: Due to the sintering process, these filters can withstand higher pressures and are less prone to deformation.

Defined Pore Structure: Offers more consistent filtration due to a well-defined and consistent pore size.

No Media Bypass: The sintering process bonds the layers together, eliminating gaps and ensuring no bypass.

Durability: Generally has a longer service life due to its robust construction.

High Dirt Holding Capacity: Offers both surface and depth filtration, capturing particles throughout the material.

Disadvantages:

Cost: Sintering process adds to the manufacturing complexity, making these filters more expensive.

Cleaning: While they can be backwashed or cleaned, removing particles trapped within the depth of the material might be more challenging compared to surface-only filters.

The choice between wire mesh pleated and sintered mesh pleated cylindrical filter elements depend on the specific requirements of your application. Consider the operating pressures, required filtration efficiency, frequency of cleaning, budget, and the criticality of the process when choosing between the two.

We are always ready to help with suggestions and quality solutions, so do not hesitate to contact with your specific requirement.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen