Stainless Steel Extruder Screen-Screen Packs-Filter Screens for Plastic and Polymer Melt

We supply extruder screen made of woven wire mesh used in extrusion processes, with smooth screening surface, with no sharp edges, burrs or acute angles. The mesh screen offers high durability, precise filtration, stable under tension and are uniformly cut and framed. Extruder screens are mainly used for plastic extrusion and polymer melt filtration in making fiber, film, and resin products.

Extruder screens provide a clean and clear extrusion for the melt filtration and plastic extrusion processing machinery. Also called polymer filter screen or melt filter screen. Extruder Screen Mesh are mainly made from high quality SS 316, SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns, and used for Plastic and Rubber Industry. Edges styles cover spot welded edges and aluminum framing.

Major Types:

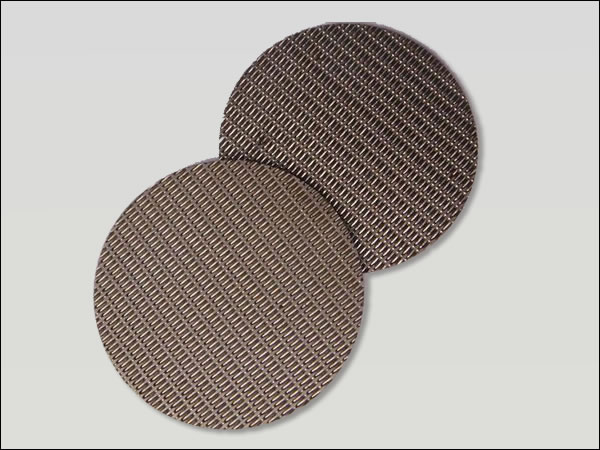

Disc / circular screen

Multilayer extruder screen packs

Single layer extruder screen

Mulity layer extruder screen

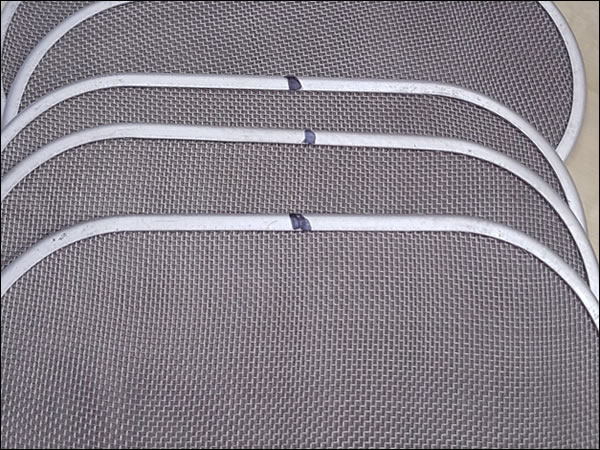

Rimmed screen

Screen filter belts

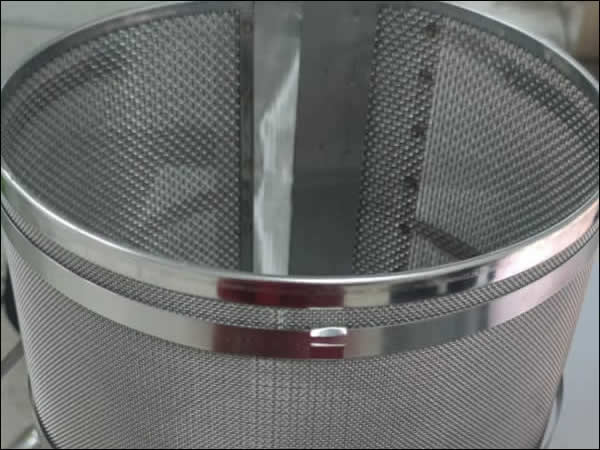

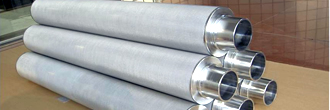

Cylindrical screens tubes

Canle pack screens

Custom screens

Edge: Aluminum framed or non-framed.

Spot welded and with or without aluminum frame

Layer: single layer or multilayer.

Material of filter screen/ filter mesh: SUS304(AISI304), SUS316(AISI316), SUS316L(AISI316L), NO.201, NO.304, NO.316 stainless steel, also nickel alloy, Hastelloy alloy, Monel and Inconel.

Extruder Screen Application

This mesh screen filter is designed to filter out impurities from molten materials like plastics, polymers, rubber, and other compounds. Major application as following:

1, Plastic extrusion to produce clean films, pipes, and profiles;

2, Polymer production to remove unmelted particles;

3, Rubber extrusion;

4, Food and pharmaceutical industries;

5,

Recycling plants for melted plastic scrap.

Screen Packs of Metal Materials and Guide for Choosing

Screen pack is extrusion filter screens of multiple layers stacked and welded into one piece used in extrusion processes to filter out impurities from molten materials. Screen packs are made from materials mainly plain steel, stainless steel and nickel alloys.

Stainless steel screen packs are much more resistant to rust than other materials. Screen packs from nickel alloy can be used in corrosive processing environment (such as from sulfuric acid, hydroflouric acid, and salt water). When choose screen packs, the working environment must be taken into consideration. Stainless Steel Extruder Screen Packs are widely applied on PC, PP, PE, PS, HIPS, PET, PVC and other plastic sheet extruder, the membrane machine, granulator, and nonwoven fabrics, color masterbatch, filler, leather chemical fiber extruder, etc.

Benifits of ss extruder filter screen packs: High filtration finness/precision; High intensity; Easy to clean; Easy to replace; High temperature resistant; Corrosive resistant.

Screen Packs for Gels and Particle Filtration from Polymer Melt

Filtration: 10-100 micron

Purpose: To filter

Gels and Particles from Polymer Melt

Form:

Screen pack with metal ring

Specification:1.15 cm in diameter, 1 mm maximum thickness

Export to USA

Multi-layer Wire Mesh Extruder Screen Set Spot Welded

Screen packs made from several layer wire meshes of different mesh sizes by welded together. The finest wire screen is in the center of the screen pack, the larger mesh opening wire screen is placed at outer sides for support and protection. The multi-layer extruder screens are arranged in a symmetrical fashion, which prevents the screen pack from accidentally being installed backwards. Multi-layer mesh screen packs are suitable for extrusion processing of plastics, polymers and fibers.

Process: Multi-layer wire mesh extruder screen sets are manufactured with different wire mesh pieces cut to desired shapes and sizes, then assembled properly and spot welded to form multilayer packs.

Welding Spots: Multi-layer mesh discs can be processed with different numbers and arrangement of welding spots according to your specific requirements.

We can produce multi-layer mesh discs with various combinations of materials: plain steel wire mesh and stainless steel wire mesh can be welded together, wire cloth of different specifications can be arranged to achieve ideal filtration.

Features:

Multi-layer extruder screen packs are extra strong, sturdy and convenient for problem free processing;

Can be assembled in proper sequence to eliminate operator error;

Multi layer screen pack can prevent foreign particles in the molten mass from going through the extrusion process;

This type of extruder screen is suitable for fine extrusion, clean and clear.

Multi-layer extruder screen packs common specifications:

Layers :2 , 3 ,4, 5 layers, or other more layers.

Material: Stainless steel(ss302, ss304, ss316, ss316L) woven wire cloth, copper wire cloth, galvanized wire mesh, aluminum alloy, and nickel alloys.

Shapes: Round, circle, disc, square, oval, rectangle, elliptical shape, other special shape

Packs Diameter 20mm - 900mm

Frame style: with or without frame, spot welded

Disc Type Wire Mesh Filter Screen - Circular Screen

Material of filter screen: SUS 301, 302, 304, 304L, 316, 316L stainless steel wire mesh, brass wire mesh, plain steel wire mesh galvanized wire mesh etc.

Material of filter screen: SUS 301, 302, 304, 304L, 316, 316L stainless steel wire mesh, brass wire mesh, plain steel wire mesh galvanized wire mesh etc.

Diameter of wire mesh discs: from 2 to 30".

Features: Neat and precise filatration; High compressive strength; Heat-resistance and rust-resistance; Wear-resistance; Acid-resistance, alkali-resistcance; Economic cost; Easily installed and replaceable.

Application: Disc filter screen is widely used in filtering of gas and liquid, separating of other medium, fuel filter, vacuum filter,used in the field of petroleum, chemical industry, chemical fiber, rubber, metallurgy, medicine and food.

301 Stainless steel Extruder screen for Polymer Melt filter

Material: Stianless steel Wire Mesh 301 Grade

Wire diameter: 0.028~0.711mm

Mesh: 10~400Mesh

Shape: Round and disc.

Application: Filters, chemical industry, mine industry, paper-making,etc.

SS 304 Filter Screen

Extruder Screen Discs

Material: SS 304

Mesh: Dutch weave wire mesh: 14/88mesh (220 my)

Disc Diameter: 134mm

Mesh Screen for Hydraulic Screen Changer

Supply to

US

80 mesh screen (177 micron)

100 mesh screen (150 micron)

130 mesh screen (112 micron)

150mesh screen (100 micron)

Melt blown Extruder Screen ( Stainless Steel Mesh)

Supply to Iran

Stainless steel mesh

Round shape

In multi-layers and single layer,

Filter for Melt brown extruder, without frame

Extruder Screen Meshes for Extrusion Machine

Supply to Pakistan

Mesh: 18x18 mesh, 32x32 mesh, 60x60 mesh

Mesh Type: Square hole woven wire mesh.

Shape: Circle, disc, round.

Extruder Screen Mesh Specifications:

| Screen Mesh Size | Diameter |

| 18 mesh | 61 mm |

| 32 mesh | 61 mm |

| 60 mesh | 61 mm |

| 18 mesh | 71 mm |

| 32 mesh | 71 mm |

| 60 mesh | 71 mm |

| 18 mesh | 91 mm |

| 32 mesh | 91 mm |

| 60 mesh | 91 mm |

7 Layer Filter Screen Pack 126mm x 66mm

Filter screen pack of 7 layers woven wire mesh:

First layer: 40 mesh

Second layer: 100 mesh

Third layer: 80 mesh

Fourth layer: 60 mesh

Fifth layer: 200 mesh

Sixth layer: 150 mesh

Seventh layer: 40 mesh

Filter screen pack exported to Indonesia

Melt Filter Pack of 3 Layer Woven Wire Mesh

Melt filter pack for extruder

Multilayer filter

Melt filter pack of 3 layers wire mesh

For

nozzle opening 3.5 mm in diameter

SS 304 Mesh Screen for Extrusion Screen Changer

Designed with screen mesh, guide, plate, buckle, stainless band, frame and cove screen

Screen: Set, 200 Mesh, Extruder

SCREEN:SET,200 MESH SS,EXTRUDER

Mesh range: 5 Mesh to 500 mesh

Polymer Flow Outside to Inside

Screen combination outside to inside

Screen materials:

Wire mesh 20 mesh + wire mesh 60 mesh

Wire mesh 18 mesh + wire mesh 8 mesh

Cove screen: Wire mesh 200 mesh.

Stainless Steel Filter Mesh for Extruder

Stainless steel filter mesh for pasta plant extruder

Filter material:

Stainless steel woven mesh

Filters dimensions: Ø mm 483

Material: inox

Wire : 0,4 mm.

Mesh : 0,6 mm

NIT: 50

Filters Ø mm 483

Filters dimensions: Ø mm 483

Material: inox

Wire : 0,75 mm.

NIT:35

Filters Ø mm 483

Filters dimensions: Ø mm 483

Material: inox /ss

Wire : 1.6 mm.

Mesh: 1.22mm x 1.07mm

Extruder Screen Filter Media: Stainless Steel Wire Mesh Weave Type

| Standard Extruder Screen Filter Media Specification | |||

SS Mesh |

Wire Dia. mm |

Aperture Size mm |

Open Area |

10 X 10 |

0.711 |

1.829 MM |

51.8 |

14 X 14 |

0.457 |

1.357 MM |

55.9 |

16 X 16 |

0.457 |

1.131 MM |

50.7 |

20 X 20 |

0.457 |

0.813 MM |

41.0 |

24 X 24 |

0.376 |

0.682 MM |

41.4 |

30 X 30 |

0.376 |

0.531 MM |

34.2 |

30 X 30 |

0.310 |

0.536 MM |

40.0 |

40 X 40 |

0.274 |

0.361 MM |

32.3 |

50 X 50 |

0.193 |

0.335 MM |

43.6 |

60 X 60 |

0.193 |

0.230 MM |

29.8 |

80 X 80 |

0.122 |

0.196 MM |

37.9 |

100 X 100 |

0.102 |

0.152 MM |

36.0 |

120 X 120 |

0.091 |

0.120 MM |

31.8 |

150 X 150 |

0.071 |

0.088 MM |

29.6 |

200 X 200 |

0.050 |

0.077 MM |

36.76 |

300 X 300 |

0.040 |

0.045 MM |

27.83 |

325 X 325 |

0.035 |

0.043 MM |

30.49 |

400 X 400 |

0.028 |

0.036 MM |

31.25 |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen