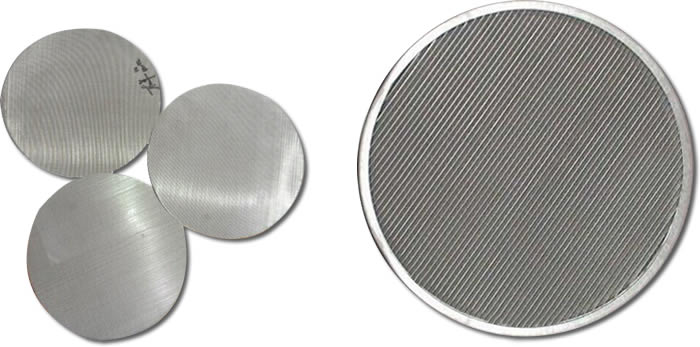

Stainless Steel Rimmed Mesh Disc for Oil Refining, Pharmaceutical and Polymer

SUS304 Stainless Steel Mesh Discs with rim edges are popularly used as refining screen in petroleum industry.

Stainless Steel Rimmed Mesh Discs are flat packs processed from 304, 304L or 316 ss mesh cloth with excellent anti-acid and anti-corrosion property.

SS Rimmed Mesh Discs for Refining supplied for European Market:

304 Grade Stainless Steel Rimmed Mesh Discs

Refining Screen Packs for Petroleum Industry

62mm Outer Diameter Maximum

54mm Inner Diameter Minimum

Mesh Count: 20 per inch

Wire Size: 28gauge

SS Grade: AISI 304

Disc Shape: Annular/ring shape

Edge: Framed/rimmed

Material options: SS316

Processing: Stainless steel mesh cloth are laser cut flat sheet, then trimmed and rimmed.

Options:

Disk layers Options: Single-layer and multi-layer; edge rimmed steel mesh multi-layer welded discs, sintered mesh disc, etc.

Mesh ranges from 20 mesh to 500 mesh to 2 micron.

Woven Wire Mesh in materials of non ferrous metals such as copper can be supplied.

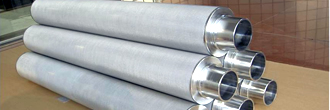

Applications: SS mesh filter discs are mainly used for petroleum, oil refining, chemical industry.

Features:

- Anti-acid and alkali;

- Direct filtration, simple process;

- Good permeability;

- Good holding capacity and definable pressure drop;

- Easy to install;

- Durable;

- High efficiency;

- Easily cleanable with excellent durability. Superior mechanical strength for problem free processing.

- Higher physical & chemical resistance.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen