Stainless Steel Wire Mesh Belt Filter Screen for Extrusion Screen Changer

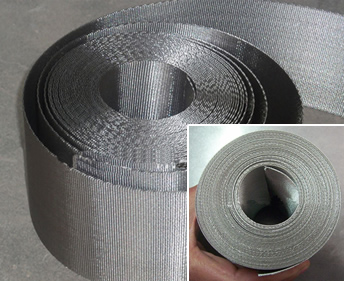

Reverse Dutch Twill Weave Wire Mesh Belts are specialized filter ribbons used in extrusion screen changers for plastics industry. The filter belts are made from high-tensile stainless steel wires, woven with finer warp wires interlaced with heavier shute wires. Reverse Dutch Twill Weave Stainless Steel Wire Mesh features high strength and precise filtration, can effectively remove contaminants from molten plastic during extrusion processes. Also known as Belt extruder screen, Ribbon extruder screen or Melt filter ribbons.

Hengmao offers two types of plastic extrusion screen:

Belt type stainless steel wire mesh filter screen and disc type extruder screen packs. Reverse Dutch Twill Weave Wire Mesh Screen is supplied in belt or ribbon type or band. Woven from quality SUS304 or 316 grade stainless steel fine wire. Designed to work with automatic contionuous screen changers used on plastic extruder.

How to choose: Wire mesh filter belts or screen packs for plastic extrusion:

Wire mesh filter belts and extruder screen packs are both used in extrusion processes, but for slightly different purposes and can be chosen for specific requirements.

-

Wire Mesh Filter Belts are typically used in continuous screen changers, to filter molten polymer during extrusion without needing to stop the process. The mesh belt continuously removes contaminants while maintaining the flow of material, making it ideal for high-volume, uninterrupted extrusion.

-

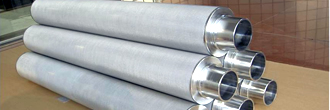

Extruder Screen Packs are typically used in batch-based filtration systems, to be inserted into the extruder to filter the material at specific intervals. The screen packs consist of multiple layers of screens that are replaced periodically, and typically used for precise filtration or varying levels of filtrations required.

Three Reasons Making Reverse Dutch Twill Weave Mesh Belt Suitable for Extrusion Screen Changers:

First, Stainless Steel Materials:

The mesh belt or ribbon is made of quality stainless steel wire materials, High tensile strength ss 304 and 316 grade wire mesh screen, offering the following features:

Anti-corrosive, anti-abrasive;

Presition mesh opening;

Smooth surface;

High hardness;

No deformation;

High temperature resistent.

Second, Unique Weaving Style Ensures High Tensile Strength and Precision Filtration:

Reverse Dutch weave wire cloth is woven using two sizes of wire. Smaller wires are used in the warp direction and are woven with a larger shute wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The fine warp and heavier shute wire construction provides excellent durability, ensuring the mesh screen can withstand the high-pressure, high-temperature conditions of extrusion processes. Also, reverse dutch weave wire mesh offers precise filtration with minimal clogging, it can efficiently remove contaminants from molten polymers and ensuring consistent product quality.

Third, Belt Size and Edge Treatment Ensures Efficient Working with Auto Continuous Screen Changers:

Wire mesh filter belts are used in automatic continuous screen changers, providing long-lasting, uninterrupted filtration during extrusion.

Filter belts can be used with all screen changers.

Filter ribbons are supplied in rolls with custom or standard length and width for various screen changers. Popular aperture covers: 72*15, 132*17, 152*24, 152*30, 260*40, 200*40, 300*40 mesh or custom according to specific requirements. The mesh ribbon width ranges from 8 cm to 25 cm to maximum 130 cm. Filter ribbon length ranges from 10m to 20 m or custom size to suit the screen changers.

Common edge or plasma weld edged. Rubbed Edges after slitting to help with tracking for Auto-Screen changers.

Plasma and laser cut parts to help prevent edges wire fraying.

Popular Products: PP/ABS/PS/plastic Extruder Filter Wire Mesh Ribbon

Material: AISI 304,304L,316,316L.

Application: Used in ribbon style continuous screen changers for plastic extrusion,melt filtration.

PP/ABS/PS/plastic extruder filter wire mesh screen: Mesh: 72/15,132/17,152/24,152/30,260/40,etc.

Roll width : 40 - 210mm, Max width: 50cm

Roll length: 10 - 20 m (Can be customized)

Standard Specifiction:

48x10 mesh RDPW 400 nominal micron

72x15 mesh RDTW 250 nominal micron

132x16 mesh RDTW 200 nominal micron

152x30 mesh RDTW 115 nominal micron

250x40 mesh RDTW 75 nominal micron

| Specification (mesh) | Belt Width | Belt Length |

| 16×120 | 7cm--21cm | 10m/15m |

| 16×150 | 7cm--21cm | 10m/15m |

| 18×120 | 9.5cm--21cm | 10m/15m |

| 38×200 | 9.5cm--21cm | 10m/15m |

| 38×220 | 9.5cm--21cm | 10m/15m |

| 38×240 | 9.5cm--21cm | 10m/15m |

| 38×250 | 9.5cm--21cm | 10m/15m |

| 38×260 | 9.5cm--21cm | 10m/15m |

| 38×350 | 9.5cm--21cm | 10m/15m |

Specification Table of PP/ABS/PS/plastic extruder screen filter ribbon: Can be customized.

| Mesh Count | Wire Diameter (mm) | Mesh Thickness (mm) | ||

| Warp | Weft | Warp | Weft | |

| 72 | 15 | 0.45 | 0.55 | 1.75 |

| 120 | 15 | 0.35 | 0.45 | 1.25 |

| 132 | 17 | 0.32 | 0.45 | 1.20 |

| 150 | 17 | 0.30 | 0.45 | 1.20 |

| 152 | 24 | 0.27 | 0.40 | 1.05 |

| 152 | 30 | 0.25 | 0.30 | 1.00 |

| 170 | 17 | 0.27 | 0.25 | 1.17 |

| 260 | 40 | 0.15 | 0.25 | 0.65 |

Application:

Reverse Twill Dutch Weave Mesh Belts are mainly used in extrusion screen changers for filtering molten polymers and in continuous filtration systems for separating solids from liquids, mainly:

Plastics processing (blown film, blow molding, sheet and film extrusion, filaments and fibers, pipe and profile extrusion, and pelletizing);

metal processing;

Food industries.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen