Sintered Wire Mesh Filter Elements - Sintered Mesh Filter, Sintered Mesh Filter Discs

Sintered mesh filter elements have an excellent strength. No inner or outer support is required for sintered wire mesh processed filters and screen packs. Forms of sintered mesh filter elements include filter basket, filter cylinder, disc and screen packs. Sintered mesh sheet applied can be five or six layer woven wire mesh with perfortated metal plate layers.

Multi-Layer Sinterd Mesh Filter Elements

General Introduction

Sintered woven wire mesh sheet can be processed into filter elements of various forms: filter basket, cartridge cylinders, pack screen, mesh discs or pharmaceutical filter plate / sheet.

Sintered Mesh Filters Features:

1. Stable high filtering precision: large extension of filtering precision(1-100 μm), the hole is not out of shape easily.

2. High strength, good rigidity: the fourth and fifth layers are the supporting layers, the six layer is the reinforcing layer, so it has high pressure resistance, mechanical strength, easy installation and easy to use.

3. High temperature resistance and corrosion resistance: maximum 480°C.

4. convenient to wash and backwash: It can be used with longer service span.

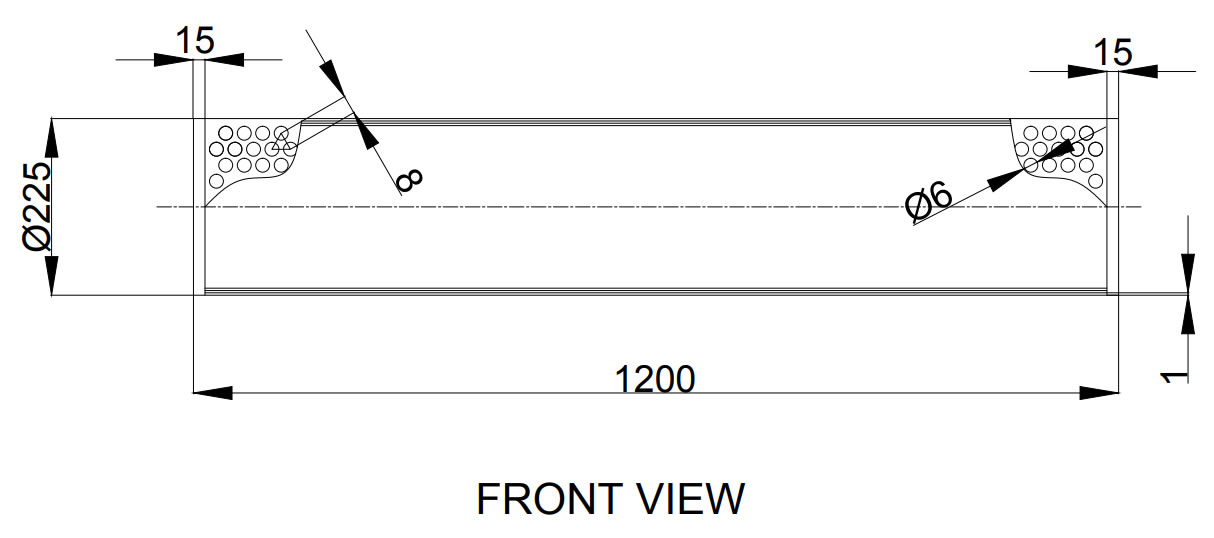

Sintered Wire Mesh Self Cleaning Filter

Structure: Filter Screen + Support Mesh+ Perforated Sheet

Structure: Filter Screen + Support Mesh+ Perforated Sheet

Perforated Sheet: 1mm thick

Filter Screen: 100 micron

Diameter: 225mm

Flow In To Out Working Pressure 4 Kg/Cm2

Operating Temp- 30 Deg.C

Material: SS316

Development Size-706 X 1200mm Long

Application-Self Cleaning Filter

Pack screen filters of Multi Layer Sintered Mesh

Sintered Multilayer Mesh Filter Disc

Export to India

Sintered multi layer filter disc 10 micron AISI 316L Grade Plain Type

Description:

Sintered Multi Layer Filter Disc, Plain

Nominal Filter Rating:10 microns

Thickness:1.7 mm

MOC: AISI-316L

Diameter: 400 mm

6 Layer Sintered Mesh Cylindrical Filter Element

Six-layer sintered mesh filter cylinder is widely used in three-in-one pharmaceutical filter plate for filtering, washing and drying.

Design can be a combination of multi-layer sintered mesh plus one layer of woven wire mesh. Wall thickness varies.

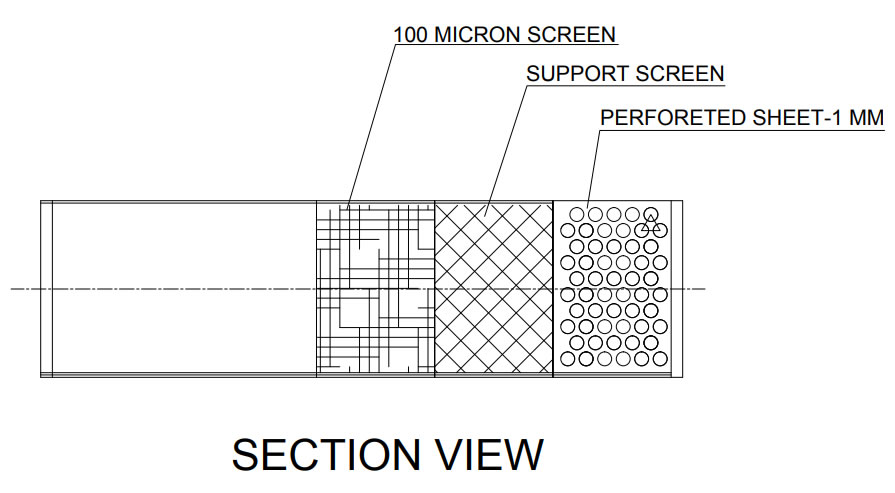

5 Layer Vacuum Sintered Woven Wire Mesh Filter Elements

5 layer sintered woven wire mesh laminated as filter media for filters.

Sintered wire mesh filter elements are simple for processing, easy cleaning and long lifespans. Common applied materials are stainless steel types 304L and 316L.

Other metals or alloys are available.

Filtration ranges from approx. 1 to 60 microns.

Standard Sintered Mesh 5 Layer Composition:

1-layer: Protection Layer

2-layer: Control Layer

3-layer: Dispersion Layer

4-layer: Support Layer

5-layer: Support Layer

Mesh layer composition: 100 + 165 × 1400 + 100 + 12 × 64 + 64 × 12

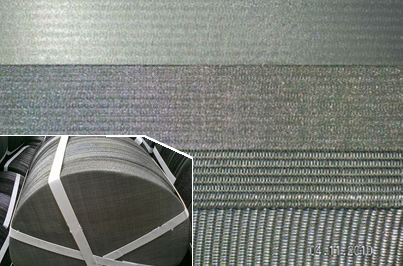

Filter Elements of Sintered Perforated Plate and Woven Wire Mesh Composite Sheet

This sintered mesh filter element is made with Perforated Sintered Mesh of sintering standard SUS304 perforated plate and several layers of square woven wire mesh (or Dutch Woven Wire Mesh) as a whole. Depending on different use conditions and purpose, a variety of combined styles of different layers and meshes are provided for options.

Structure and benefits:

Strong and rigid perforated metal works as support layer while the woven wire mesh layers work as the filter layer. The perforated metal (stainless steel) support layer and woven wire mesh composite sintered sheets have excellent reverse cleaning effect and less pressure drop loss.

Uses:Filters processed from Woven wire cloth and perforated plate sintered sheet is widely used in the industries, such as: water treatment, beverage, food, metallurgy, chemical and pharmacy. With support layer already in the sintered sheet, it can be processed directly into filter elements for various uses.

Filter Elements Specification:

1, Perforated plate is SUS 304, woven wire meshes layer are SUS316 or SUS 316L (AISI316L). Special Alloys

like Hastelloy, Monel , Inconel are acceptable based on customer's requirement.

2, Can be made into specific forms of filter products according to different requirements.

| Filter Model | Filter Rating(u) | Structure | Thickness(mm) | Weight(kg/m2) | Porosity(%) |

| SPW 4-2.0T | 2-200 | 30+Filter layer+30+Φ4x5Px1.0T | 2.0 | 6.7 | 57 |

| SPW 4-2.5T | 2-200 | 30+Filter layer+30+Φ5x7Px1.5T | 2.5 | 9.8 | 50 |

| SPW 5-3.0T | 2-200 | 60+Filter layer+60++20+Φ6x8Px2.0T | 3.0 | 11.8 | 50 |

| SPW 5-3.5T | 2-200 | 20+Filter layer+20+10+Φ8x10Px2.0T | 3.5 | 12.6 | 54 |

| SPW 5-4.0T | 2-200 | 20+Filter layer+20+10+Φ8x10Px2.5T | 4.0 | 14.2 | 55 |

| SPW 5-4.3T | 5-200 | 20+Filter layer+20+10+Φ10x13Px3.0T | 4.3 | 16.9 | 50 |

| SPW 5-5.3T | 5-200 | 20+Filter layer+20+10+Φ10x13Px4.0T | 5.3 | 20.6 | 51 |

Note:

1. The filtration layer is decided by the customer as long as the filter precision is within our specified ranges.

2. We can also make the mesh with other special structures as requested by the customer.

3. The porosity takes that of 20 mesh as criteria.

Learn more about Sintered Mesh Filter Media.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen