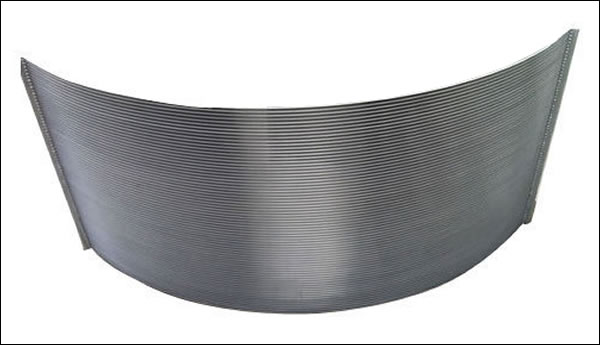

Metal Wire Sieve Bends for Coal Mining and Other Screening Uses

We offer Stainless Steel Wedge-Wire Curved Filter Panels, Sieve Bends for Mining Screening and Aggregate Screening uses. Sieve bend screens mainly used in static sieves system of mining screening, coal plants processing for dewatering or classifying. Common Range of slot: 0.3-1.0mm. Bend curving angle:45 and 60 degree. It is made from surface profiles and support profiles, supplied in arc form.

Technology:

The wedge wire construction method used is the latest, ultra clean TiG and plasma welding system. This method of construction guarantees mining screen integrity, eliminating the risk of bypass and the presence of extractables derived from any bonding agents.

Specification

Sizes are compatible with Alpine, Werner Phleider, and other OEM equipment.Available micron ratings range from 2 - 200.

Etching available for mesh/size identification

Filter Ratings: Similar to the filtration of woven wire mesh used, can be down to 5 micron.

Filter sizes: The outer sizes can be varied to meet your specific requirements.

Features

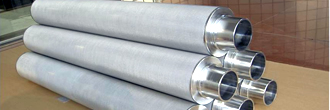

Composed of surface profile with High open area,

non clogging filter surface;

Spirally wrapped around the axial support;

Accurate, narrow slot openings;

Triangular wedge wire design creates orifice effect;

Cake discharge by back washing.

| Name | Sieve Bend Screen, DSM Screen |

| Material | SS304, 316, 316L, 2205, 2507, or customized |

| Gap size | 100 microns, 150 microns, or customized |

| Sizing | Down to 0.008 inch |

| Angle | 30° 45° 60° 90° 120° 270° 300° |

| Radius | 1018mm, 2036mm, or customized |

| Width | 20 – 120 inch |

| Application | Mining and mineral processing industries, pulp and paper, dewatering, chemical, food, starch (fiber removal), cement, sugar mill screen, sewage treatment, textile mills, etc. |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen