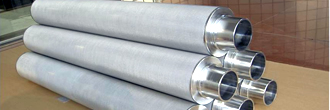

SUS 304/304L/316/316L Pleated Wire Mesh Filter Elements for Cartridge Filter System

Stainless steel wire mesh pleated filter elements are cylindrical filters made with woven wire meshes as filter media. Stainless Steel Wire Mesh Pleated Filter Elements mainly serve in filtration of high molecular polymer in the field of medicament, foodstuff, petroleum, chemical industry and electron; the filtration of the hydraulic oil and the disposal of water. The pleated multi-layer screen wire cloth filter layer offers extended filtration area and high dirt control capacities. Coarse woven wire mesh layers are pleated with the filter media layer together to form the pleating. Then welded together.

Filter elements processed with stainless steel woven wire cloth as filter medium, have such advantages of good strength, fastness, easily cleanable, heat-resistance and economic cost.

Filter elements processed with stainless steel woven wire cloth as filter medium, have such advantages of good strength, fastness, easily cleanable, heat-resistance and economic cost.

Features of Stainless Steel Pleated Filter Elements in General:

High dirt holding capacity

High reliable standard specifications

Stainless steel pleated filter element has low pressure drop due to high porosity

Pleated filter element has accurate filtration rating

Easily cleanable by conventional chemical cleaning and with a long life-span

Filtration area of pleated stainless steel filter element is increased by pleating

Pleated filter elements can use ultrasonic, chymistry to clean, and can be repeatedly used; can also be bounce-back cleaned without dismantling on the product line, then saving the time

Stainless steel pleated filter elements have strong corrosion and acid and alkaline resisting property. Durable, reusable, save cost.

Structures and Layers of Pleated Candle Filter Elements:

Structure:

1.Stainless steel material free from blur ensures a long life span.

2.Outside protection cylinder (made of perforated stainless steel plate) can protect the candle filter element from unexpected damage at installation.

3.Pleating waves increase the filtration area, enhance product lifespan and reduce operation cost.

4.Taper design at the end increases flow and avoid low flow area.

5.Quality imported sintered fiber web enjoy super filtration and repeated cleaning.

6.Internal hexagonal design to make the dismantle and loading of the elements easy, also avoid flow decreasing of the joint part.

7.The pressure resistance of stainless steel supporting inside core can reach 175bar.

Main Fittings and Components for Pleated Wire Mesh Candle Filters:

Thread, flange, tie rod, cap, etc.

SS Pleated Filter Main Connector Connections:

1. Standard connector(220,222,226).

2. Snap coupling.

3. Thread connection.

4. Flange connection.

5. Rod connection.

6. Special customization.

General Technical Data:

1.Working pressure:30Mpa

2.Working temperature:300 degree celcuis

3.Dirt holding capacity:16.9~41mg/cm2

Material: Stainless steel 304,304L,316,316L

Quality Guarantee:

All our stainless steel pleated filter elements must pass following tests:

Bubble point test / fabrication integrity test (as per ISO 2942)

Performance test (Filtration efficiency & DHC) (ISO 16889/4548-12/19438)

Collapse/ burst pressure test- as a continuation of perf. test – up to 30bar (ISO 2941)

Other specific tests needed for quality control of products.

Stainless steel filter cartridges with pleated extended filter area are used in the following scopes:

Stainless steel filter cartridges with pleated extended filter area are used in the following scopes:

1. Environmental, chemical, food, pharmaceutical, petroleum, water treatment filtration industry;

2. Iron and steel melting, power generation, marine purification, drinking water treatment, air filter, oil filter and others.

Pleated Cylindrical Filter Elements made of metal mesh (AISI 304 Stainless Steel)

Metal Mesh Pleated Cylindrical Filter Element ( 1Micron)

Outer diameter 158 mm, inner diameter 90 mm, length 996 mm ± 2 mm

Filtration: 1 µm, 12 pieces, Water flow:10 l/sec.

Mesh material: SS 304

Metal Mesh Pleated Cylindrical Filter Element ( 5 Micron)

Outer diameter 158 mm, inner diameter 90 mm, length 996 mm ± 2 mm

Filtration: 5 µm, 12 pieces, Waterflow: 10 l/sec.

Mesh material: SS 304

Pleated Wire Mesh Filter Cartridge Element

Technical detail per attached drawing.

Pleated Wire Mesh Filter

Specification:

Cartridge element ( 5 micron)

Wire mesh 20#

Perforated plate: Thickness 1mm

Perforated plate (outside layer): hole diameter 6mm

Perforated plate (inside layer): hole diameter 3mm

RB plate thickness: 1mm

Fold: 32

All materials: SS. 304

OD.: 115mm

ID.: 47mm

Length: 277mm

Stainless Steel Woven Wire Mesh Cloth Pleated Filter Elements

Made of stainless steel fine woven wire cloth, square or rectangular opening.

The pleated layers are normally two or three layers of woven wire mesh, together with inside perforated metal tube support. The outside layer of perforated metal tube is optional.

Outer layer mesh:

Specification of Woven Wire Mesh Pleated Filter Cartridges: Filtration, Layers, Air Permeability:

| Designed Filter Fineness (um) | Wire Mesh Protection Layer (mesh) | Fine Wire Cloth Control Layer (mesh) | Neutral Layer (mesh) | Strengthening Layer ( coarse mesh) | Layer Thickness (mm) | Air Permea-bility ( L / Min / cm2 ) |

Bubbling Pressure | |

| 1 | 200 | 400*3000 | 200 | 12*64 | 64*12 | 1.7mm | 1.81 | 360-600 |

| 2 | 100 | 325*2500 | 100 | 12*65 | 64*13 | 1.7mm | 2.35 | 300-590 |

| 5 | 100 | 200*1400 | 100 | 12*66 | 64*14 | 1.7mm | 2.42 | 260-550 |

| 10 | 100 | 165*1400 | 100 | 12*67 | 64*15 | 1.7mm | 3 | 220-500 |

| 15 | 100 | 165*1200 | 100 | 12*68 | 64*16 | 1.7mm | 3.41 | 200-480 |

| 20 | 100 | 165*800 | 100 | 12*69 | 64*17 | 1.7mm | 4.5 | 170-450 |

| 25 | 100 | 165*600 | 100 | 12*70 | 64*18 | 1.7mm | 6.12 | 150-410 |

| 30 | 100 | 400 | 100 | 12*71 | 64*19 | 1.7mm | 6.86 | 120-390 |

| 40 | 100 | 325 | 100 | 12*72 | 64*20 | 1.7mm | 7.1 | 100-350 |

| 50 | 100 | 250 | 100 | 12*73 | 64*21 | 1.7mm | 8.41 | |

| 75 | 100 | 200 | 100 | 12*74 | 64*22 | 1.7mm | 8.7 | |

| 100 | 100 | 150 | 100 | 12*75 | 64*23 | 1.7mm | 9.1 | |

| 150 | 50+100+50+30+30+100+50 | 2.0mm | 25 | |||||

| 200 | 40+80+40+20+40+80+40 | 2.0mm | 26 | |||||

Woven Meshes Specifications Applied for Pleated Wire Mesh Filters:

| Item | Apperture | Wire | Material | Width | Length | |

| [mm] | [mm] | |||||

| PW1 | 0.043 | 0.035 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW2 | 0.16 | 0.1 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW3 | 0.25 | 0.16 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW4 | 0.3 | 0.2 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW5 | 0.3 | 0.2 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW6 | 0.4 | 0.22 | plain weave | AISI 304 | 2,850 | 30,000 |

| PW7 | 0.4 | 0.25 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW8 | 0.5 | 0.2 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW9 | 0.5 | 0.2 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW10 | 0.5 | 0.2 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW11 | 0.5 | 0.3 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW12 | 0.5 | 0.3 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW13 | 0.55 | 0.22 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW14 | 0.63 | 0.4 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW15 | 0.63 | 0.4 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW16 | 0.71 | 0.3 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW17 | 0.71 | 0.3 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW18 | 0.8 | 0.3 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW19 | 0.8 | 0.47 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW20 | 1 | 0.3 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW21 | 1 | 0.5 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW22 | 1.2 | 0.4 | plain weave | AISI 316 | 2,040 | 30,000 |

| PW23 | 1.2 | 0.5 | plain weave | AISI 304 | 1,500 | 30,000 |

| PW24 | 1.5 | 0.5 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW25 | 2 | 0.6 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW26 | 2 | 0.8 | plain weave | AISI 316 | 1,300 | 30,000 |

| PW27 | 2.5 | 0.8 | plain weave | AISI 304 | 1,300 | 30,000 |

| PW28 | 0,9x2,7 | 0.6 | plain weave | AISI 304 | 1,520 | 30,000 |

| PW29 | 0,8x2,4 | 0.6 | plain weave | AISI 304 | 1,300 | 30,000 |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen