Pleated Filter Elements

Hengmao manufactures and supplies both non-metal and metal wire pleated filter elements: Metal mesh pleated candle filters, PP pleated micron membrane filter elements for water treatment, glass fiber pleated oil filters.

Filter Media:

Metal mesh,

Sintered metal web;

Non metal fabrics ( PP, Fiberglass, Polyester ).

Classification

Pleated filter elements can be classified based on:

The shape of the filter element(cylindrical filter, conical, etc.);

Application (liquid filter, gas filter, etc.);

Industry-specific categorizations (food-grade, pharmaceutical-grade filter element, etc.)

Pleated 304 SS Wire Mesh - Cleanable, Replacable

Supply to Belgium

304 SS Wire Mesh Filter Element - Standard Filter Area 38m2

Filter area: 38 m2

Collapse DP: 0.2 MPa

Gasket material: Klinger-sil

Hardware material: SS 304 Perforated Plate

Medium Material: Pleated 304 SS Wire Mesh

Filtration Rating: 99.9% 3 micron min.

Out support mesh thick:1mm

Inside support mesh thick: 2.5mm

Size: 2m length

Type: Cleanable, replacable, reusable

Filter Element 304 SS Wire Mesh - Filter Area 76m2

Filter area: 76 m2

Collapse DP: 0.2 MPa

Gasket material: Klingersil

Hardware material: SS 304 Perforated Plate

Medium Material: Pleated 304 SS Wire Mesh

Filtration Rating: 99.9% 3 micron min.

Out support mesh thick:1mm

Inside support mesh thick: 2.5mm

Size: 2m length

Type: Cleanable, replacable

Pleated Filter Element

Pleated filter element made of polyester spunbound media and galvanized steel spiral core

Supply to Korea

Bag House Filter Elements for liquid and air filtration system

Specification:

Bag Filter Elements for Varied Filter : 2000L x 162W x Polyester Spunbonded.

Drawing for Pleated Filter Element

Material

| NO. | Description | Unit | Specification | Remarks | |

| 1 | Material | PET Spunbonded + condudivity bubble coating | |||

| 2 | Weight | g/m2 | 230 ± 30 | KS K0514 | |

| 3 | Thickness | mm | 0.55 ± 0.1 | KS K ISO 5084 | |

| 4 | Tensiee | Length | kgf | 110 above | KS K0520 |

| Width | kgf | 80 above | KS K0520 | ||

| 5 | Air Permiabos | 125PA | cm2/cm3/sec | 7 ± 2 | KS K ISO 923/ |

| 200PA | cm2/cm3/sec | 11 ± 3 | KS K ISO 923/ | ||

| 6 | Bust | kgf/cm3 | 20 above | KS K ISO 13938-1 | |

| 7 | Emission | levee 4 above | KS K0590 | ||

| 8 | Surfactvesitame | 10 * 10^ under | AATCC 76 | ||

| 9 | Operating Temp. | 110 | |||

Material

| NO. | Description | Material | Remarks |

| 1 | Up Cap | Galvanized Steel | 1.01 |

| 2 | Media | Polyester Sounbond | 4.4 m2 |

| 3 | In Core | Galvanized Steel (Spiral Core-Embossing Type) | 0.35T |

| 4 | Down Cap | Galvanized Steel | 1.0T |

| 5 | Sealant | Poly-Urethane | |

| 6 | Band | Polyester Fabric | |

| 7 | Accessory | Wire Ring Head |

Pleated Cylindrical SS Wire Filter

Cylindrical pleated SS wire filter for hydraulic valve component

Screen: Pleated wire mesh cloth shaped into waved corrugated

Formed into cylinder welded or mechanically locked

Pleated Cylinder to be assembled on to the hydraulic component

Pleated Filter of Micro Fiber Filter Media

Type: FIBERGLASS pleated fiber

Features:

High efficiency;

Wide application;

Economic cost;

Large surface area

Pleated Oil Filters with Glass Fiber Filter Media

Oil Filter Element designed with metal support tube, metal support mesh and glass fiber filter media.

The optimized pleated filter element design is used in liquid filtration, including lube, transmission, hydraulic and fuel application.

This filter element has multi folded filter layer, increasing filter area and high structure strength.

1.End cap: made of zinc-plated metal material.

2.Support tube: made of carbon steel with many filter holes

3.Support mesh: Ultrafine metal wire mesh

4.Filtration material: superior glass fiber

5.Fitration rating: 3~200 micron (1 micron on request)

6. Structural strength: 1.0 MPa,2.0 MPa ,16.0MPa ,21.0MPa

7.Tempereture renge: -30℃ to +℃ 100 for FPM seal material to -10℃

0℃ to +100℃ for water absorbing filter material

Features

1.Conventional fan-pleat filter element avoids unused volume

2.The laid-over pleat geometry of filter elements maximizes available area and ensures uniform flow distribution throush the filter element.

3.High strength construction(optional)

4.Extended filter element serviced life (same space envelope )

5.Consistent performance throughout filter element service life

Oil Filter Element

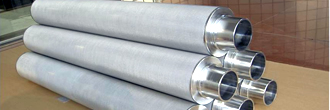

Metal Mesh Pleated Candle Filters

Metal Mesh Pleated Candle Filters

With pleated wire mesh or sintered fiber web as filtering materials, Metal Structure Pleated Filter Elements mainly serve in filtration of high molecular polymer, long fiber, short fiber, meltdown in thin film production, also drugs, hydraulic oil, disposal of water, hot gas, etc.

Pleated metal filter elements offer different properties according to options of the filter media:

Filter media for Multi-layer Pleated Filter Elements can be stainless steel sintered fiber web and stainless steel weaving screen wire cloth.

PP Pleated Micron Membrane Filter Elements

Type: POLYPROPYLENE / PP pleated filter

Features:

Large surface area meltblown;

Low initial pressure drop;

High particle retention;

High filtration efficiency

Material: polypropylene / PP

Material: polypropylene / PP

Length: 5 - 50 inch

Pore size: 0.1/ 0.2/ 0.45/ 0.65/ 1/ 3/ 5/ 10/ 20/ 30/ 50/ 60 micron

Filter cage: polypropylene

Layer support: polypropylene

Filter end caps: DOE, SOE, customized

Outer diameter: 69mm

Typical Applications:

-- Electronic industry

-- Food industry

-- Chemical industry

-- Pharmaceutical industry

Membrane filter cartridge in water treatment field

-- Drinking waste water treatment

-- Waste water treatment, daily waste water treatment, oily waste water treatment, food industry waste water treatment, electroplating waste water treatment, papermaking wastewater treatment

-- Desalination

| Cartridge Type | Micron Ratings | Filter Media | Length | Gasket/O-ring | End Cap |

| PPMP: PP Membrane Pleated Filter Cartridge | 0.1:0.1μm | P: Polypropylene | 5: 5" | S: Silicone | A: Flat Gasket Double Open End |

| 0.22:0.22μm | 10:10" | E: EPDM | B: 222 O-ring with Flat End | ||

| 0.45:0.45μm | 20:20" | N:NBR | C: 226 O-ring with Flat End | ||

| 0.65:0.65μm | 30:30" | V: Viton | D: 222 O-ring with Fin | ||

| 1:1μm | 40:40" | E: 226 O-ring with Fin | |||

| 3:3μm | 50: 50'' | ||||

| 5:5μm | Other Customized Sizes |

||||

| 10:10μm | |||||

| 20:20um | |||||

| 30:30μm | |||||

| 60:60μm |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen