Hydraulic Filter Element for Hydraulic Oil and Hydraulic Water System

Hydraulic filter element is used in the hydraulic system to protect the components by removing the the contamination particles. Hengmao supplies various wire mesh filter screen, mesh disc, filter cartridge and cylinder filter elements used for hydraulic system control.

Hydraulic filter elements are usually installed in the filter entrance point of hydraulic system, using for filtering prill and impurities in the fluid medium and protecting the normal work of equipment. When the fluid pass the filter, its impurities will be blocked, and the clean filtrate will expel from the exit of filter.

Hydraulic filter elements are usually installed in the filter entrance point of hydraulic system, using for filtering prill and impurities in the fluid medium and protecting the normal work of equipment. When the fluid pass the filter, its impurities will be blocked, and the clean filtrate will expel from the exit of filter.

The foreign particles can cause damage to hydraulic system components because hydraulic oil is easily contaminated. The wear of hydraulic system components is dependent on this contamination, and the existence of metal parts in hydraulic system oil accelerates its degradation.

Hydraulic filter elements are used to remove dirt and particles from fluid in a hydraulic system.

Hengmao supplies sintered metal powder pipe filter and wire mesh pleated stainless steel filter elements used for hydraulic system control with high dirt holding capacities and excellent contamination removing performance.

Standard Specifications:

| Filter Media Material | HV fiberglass, filter paper, stainless steel wire mesh |

| Filter accuracy | 1, 3, 6, 12, 25 …um |

| Pressure | 1.0Mpa, 2.0Mpa, 16.0Mpa, 21.0Mpa |

| Application field | hydraulic system, lubrication system |

| O-Ring |

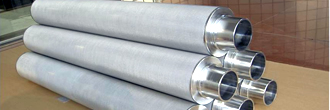

Sintered Mesh Hydraulic Filter Cylinder

We have various types of Sintered mesh hydraulic filter elements. Following information will help us learn more about your inquiry:

We have various types of Sintered mesh hydraulic filter elements. Following information will help us learn more about your inquiry:

1. The drawing of the filter

2. The filtration

3. The material

4. The diameter of the filter element

5. The wall thickness of the filter

Sintered mesh filter element is made of sintered mesh after cutting and precision welding.

Advantages:

1. Strength: With support layers, the pleated filter elements offer high mechanical strength and compressive strength.

2. Easy to clean: Especially suitable for backwashing.

3. Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

4. High temperature: 480 °C. can withstand high temperatures.

5. Corrosion resistance: SUS316L, 304 materials offers excellent corrosion resistance.

6. Filtration: Filtration range of 1μm-200μm. Reliable filter performance.

7. Stability: The filter elements have protective metal layer, also the filter media is made with sintering process, these two factors make filters not easily to deform.

Applications:

Used in water treatment, pharmaceutical, chemical, food, beverage, oil filtration and etc.

Hydraulic Water Filter Elements

Hydraulic Water Filter Elements is composed of a variety of composite materials by a special process. It can not only filter mechanical impurities, but also further facilitate realization of the purification medium.

Hydraulic Water Filter Elements is composed of a variety of composite materials by a special process. It can not only filter mechanical impurities, but also further facilitate realization of the purification medium.

Selection of the main coalescence through a glass fiber filter or the surface-treated polyester fiber as coalescing media, through a special design of the structure of the filter medium, such that the filter medium has good coalescence performance. Filtration precision up to 0.1μm.

Filter frame material: stainless steel and other materials

Performance:

Accuracy Range: less than 0.3 microns, 0.3 microns, 0.5 microns, 1 micron, 5 micron, 10 micron

Initial pressure: ≤0.4psig

Replace the pressure: <0.6psig

Operating temperature: 0 ~ 120 ℃

Filter theory: oil, water and other liquid droplets, the ultra-fine fibers is the interior of the coalescer to capture these micron fibers to form a tortuous flow path, forcing the solid particles and liquid droplets in the inertial impaction, interception and diffusion intercept the direct role of the three filtering mechanism is captured microfiber, so that the surface tension of the liquid droplets coalesce into larger droplets due to gravity, settle to the bottom of the container of large droplets.

Hydraulic Water Filter Elements using high-density gradient of glass fiber, designed to reduce the overall dropout damaged pipe monolithic structure, the filter surface is hydrophobic, oleophobic treatment, can meet various levels of precision requirements.

The polyester fiber mesh filter material is generally a synthetic material with good compatibility with various fluids. A multilayer structure using a spiral cartridge roll made, each with different properties of the fibers, each fiber by controlling the shape, size, thickness and density and other parameters to achieve the desired filtering accuracy.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen