Sintered Metal Powder Filters: Metallic Porous Filter Candle / Tube / Cylinder and Disc Filters, in SS304L, SS316L and Titanium

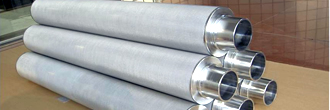

Hengmao offers two forms of sintered metal porous filters: tubular / pipe filters and disc screen filters. Metal porous cylindrical filters are available in diameters from 13.5 to 135mm, continuous lengths up to 1500mm, and with a full range of sinter bonded end caps including 222, 226, flanged, threaded, closed and finished. Used in melt processing of chemical fiber, petroleum, water treatment, chemical industry, electric power, pharmaceutics, machinery, metallurgy, ceramics, dispose of sewage, foodstuff and beverage, cosmetic etc. Filter media: Sintered metal porous powder.

A sintered powder filter is a type of filter element made from metal alloy powders that have been processed through a sintering technique. Sintering involves heating the powder particles to a temperature below their melting point, causing them to bond together due to diffusion, without fully melting. This process creates a porous but strong metallic structure.

Sintered powder filter offers a depth filtration mechanism, capturing contaminants throughout the thickness of the filter, not just on the surface. These filters are known for precise and consistent pore sizes, high temperature resistance, and excellent mechanical strength.

Main Shape Types of Sintered Powder Filters:

Disc:

Shape: Circular and flat.

Cylinder (or Tube):

Shape: Cylindrical, hollow in the center. Range from small tubes to larger cartridges.

Sintered powder cylindrical filter is widely used in industrial processes for fluid and gas filtration. The hollow center allows for inside-to-outside or outside-to-inside flow configurations, depending on the setup. They can be used in backwashing systems and are ideal for applications requiring high flow rates and extended service intervals.

Sheet/Plate:

Shape: Flat and rectangular or square.

Special shape:

Used in specific applications where the flow dynamics and distribution are crucial.

Conical:

Shape: Cone-shaped.

Used in specialized filtration setups where flow distribution and direction are essential.

Filter Media: Sintered Metal Porous Powder

Materials Applied:

1. stainless steel 304/304L/316/316L

2. Copper, brass

3. Monel wire, inconel

4. Titanium, special alloy steel hastelloy,etc.

Features:

1.High mechanical strength with the ability to maintain a steady filter rating under high pressure

2.Easy to clean and repeated use

3.Good corrosion resistance, good heat resistance

4.Easy to fabricate

5.Long service life

Why Sintered Powder Filter Elements? - Benefits over Sintered Mesh Filter Elements

Sintered powder porous filter cartridges are suitable for applications with high temperature and high differential pressure requirements.

Short comings and benefits compared with Sintered Mesh Filter Elements:

Sintered metal powder filter cylinders are typically less permeable than the equivalent stainless steel sintered fibre or sintered mesh product.

Benefits:

1, Sintered powder cylinder filters are extremely robust and suitable for use in the most demanding operating conditions;

2, Sintered Powder filter elements can be made of a wide range of materials, including stainless steel, titanium, nickel, bronze, Inconel, Monel and Hastelloy, to suit different uses;

3, Economic and simple structure: Sintered powder cylinder filter

has simple structure and costs less.

Sintered Metal Porous Tubular Filters - sintered filter candles

Sintered Porous Pipe filter elements, also known as Sintered Powder Filter Candles, are widely used in chemical fiber, petroleum, chemical industry, electric power, pharmaceutics, machinery, metallurgy, ceramics, dispose of sewage, foodstuff and beverage, cosmetic etc.

Advantages:

1, High strength

2, No possibility of media migration

3, Wide operating temperature range

4, High dirt holding capacity

5, Excellent corrosion resistant

6, Pipe filter elements provide high flow rates at low pressure drops

Filtration rating(micron) of cylinder type filter elements:2,5,10,20,40,75,100

Any outline size is available at customer's requirement.

Sintered filter candle export to USA:

Sinter Metal Powder Filter

Dia: 115 mm

Thickness: 3mm

Filter Level: 40 microns

Material: SS316L

Sintered Metal Powder Tubular Filter

Supply to Thailand

Ti 0.45 micron x Length 40 inch. x OD 60 mm, connect thread

SS 316L 1 micron x Length 40 inch. x OD 60 mm, connect thread

SS 316L 5 micron x Length 40 inch. x OD 60 mm, connect thread

SS 316L 50 micron x Length 40 inch. x OD 60 mm, connect thread

Sintered Metal Powder Cylindrical Filter

Cylindrical Sinter Powder Filter

Size: 305 mm diameter x 400 mm long x 6 mm thick

Both ends: Open on both ends

Micron rating: 10 micron.

Stainless steel Sintered Porous Metal Filter Disc

Stainless steel Sintered Porous Metal Filter Disc

316L Stainless steel Sintered Porous Metal Filter disc has the features of good permeability, big capacity, high strength, no bracket required, heat resistance, corrosion resistance, easy to clean, high filter rating, etc.

Characteristic:

1. The average filtration precision: 5-80 um;

2. Large flow, high filtration efficiency;

3. Good unity.

Industries Served:

1. Food and beverage industry.

2. Chemical and pharmaceutical industry (pharmaceutical products,plastic Recycling and Precision sieving of powders,etc.)

3. Petrochemical industry.

4. Water treatment system.

5. Aerospace industry.

Filter Media for SS Sintered Power Pipe Filter- Stainless Steel Sintered Porous Metal Powder

Sintered stainless steel powder is normally formed by compressing a controlled blend of metal particles into their “green” state and sintering them in a controlled atmosphere furnace into a rigid media. The resultant medium is typically between 2-3 mm thick, ungraded through its thickness and has a fairly tight pore size distribution. During the initial compression of the medium, the high pressures gives rise to a smooth surface finish and high density media with a maximum void volume of around 50% This lowvoidage and high thickness leads to low permeability.

Filter Disc Products

Powder Sintered Metal Disc Grade SS316L

Export to Malaysia

Material: SS316L

Thickness: 10mm

Diameter: 760mm

Filtration grade: 20 µm

Powder Sinter Metal Disc SS304L

Material: SS304L

Thickness: 10mm

Diameter: 760mm

Filtration grade: 20 µm

Titanium powder sintered filter cartridge/porous metal filter pipe

Micron sintered metal powder filter cartridge for liquid and gas pre-filtration. Suitable for high temperature and pressure conditions.

Titanium Powder Sintered Filters Features:

1. Washable

2. Mechanical strength

3. Metal structure and sintered at high temperature

High temperature and pressure resistant.

Cartridges can work under extreme

high temperature and pressure conditions.

4. Wide chemical compatibility:

Cartridges can resist to strong acid, alkaline

and Ozone Oxidation.

5. Long life:

Cartridges can be backwashable and cleaned

by chemical solvent, hot water,steam

Typical Applications

Suitable for the extreme operating enviroments, steam filtration.

Pharmaceuticals:Prefiltraion and decarbonate filtration.

Food & Beverages:Viscous liquid with high temperature.

Fine Chemicals: Strong Acid and Alkaline filtration.

Water:Filtrate the O-zone containing water.

Cartridge Cleaning Methods:

* Pharmaceutical, Food & Beverage industries:

Hot water flush; Steam clean; Water Backwash

Brush clean; Compress air blow.

* Chemical Industry:

Chemical Solvent clean; Ultrasonic cleaning

High pressure water spray rinsing; Acid dipping.

Sintered Metal Powder Filter

Specification:

| Material Of Construction | |

| Filter media | Titanium powder Sintered |

| SUS316 powder Sintered | |

| Nominal Micron | TI: 0.45um, 1um, 5um, 10um, 20um, 50um |

| STS: 1um, 5um, 10um, 20um, 50um | |

| STP: 1um, 5um, 10um, 20um, 50um | |

| Dimensions | |

| Outer diameter | 60mm/80mm |

| Length | 10'' ,20'',30'',40'' |

| filtration area(m2) | 0.65m2 per 10'' |

| pore size(um) | 0.04,0.1,0.2,0.45,0.6 |

| operating conditions | |

| Max working temperature | Ti:220C |

| steel 316l:300C | |

| Max differential pressure | 4 bar |

| PH value compatibility | 1-14 |

| Typical application: | |

| steam filtration | |

| pharmaceutical industry | |

| food and baverage | |

| fine chemical | |

| water | |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen