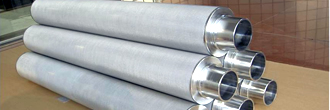

Spiral Wound Welded Perforated Tube for Filter Cores

Perforated Tube Spiral Welded is manufactured from quality perforated metal via superior technology in spiral welding, used as Filter Core in a variety of filtration systems. Spiral welded filter cores are mainly used in industries such as water treatment, pharmaceuticals, petrochemicals, and food and beverage. Stainless and steel perforated spiral wound welded tubes provide the structural support for filter media, enabling effective fluid passage while trapping particulates.

Spiral Wound Welded Perforated Filter Tube Core - in Stainless Steel 304 and 316 and Carbon Steel

We supply a diverse range of perforated metal filter cores to meet varying filtration systems.

Common lengths available: 9-7/8", 10, 19.5, 20, 30, and 40 inches.

9-7/8" to 40" long perforated tube spiral wound weld filter element cores

Materials: Carbon/Tinned steel, 304SS, and 316SS material.

Standard in 1inch ID x 2-7/16OD

Various sizes available.

Perforated hole can be round or square.

Structures

Perforated Pipe / Tube spiral welded in Spiral heliarc welded seam.

Use

Spiral welded filter cores are used in various filtration systems, including but not limited to:

- Water Treatment Plants

- Pharmaceutical Manufacturing

- Sand Control

- Industrial Filtration

- Hydraulic Filtration

- Aerospace

- Oil Drilling

Round Hole Perforated Steel Tubing

Perforated steel tube and filter core for industry

Type:

SPIRAL PERFOREATED FILTER TUBES

Filter Core Spiral Welded Material:

CRC

14 GA. Thickness 0.075 inch +/- 0.005 inch

Material Option:

CRC

14 GA. Thickness 0.180 inch +/- 0.005 inch

Perforation: 1/8 diameter on 1/4 staggered centerd 23% open area

Weld: Heliarc ( TIG) smooth outside surface

Finish: Clean without rust-deburr ends.

Spiral welded perforated filter tubes

Supply to Finland

Tube Core Spiral Welded Drawin

Dimensions in the drawing in inches.

Spiral Welded Perforated Tubes

Spiral welded perforated tubes made from steel

Material: Perforated Steel Sheet, Round Staggered

Diameter 0.250 inch x 0.312 inch stagger

Hole size and spacing as well as the OD , thickness , and length as following:

Spiral Welded Perforated Tube,

4 " OD x 0.165" Wall,

Gauge: 8

Perforation pattern: 1/4 inch hole x 5/16 inch staggered centers

Open area: 58%

Spiral heliarc welded seam

Smooth outside surface

Perforated Tubes Spiral wound welding SS 316L and SS 304L

Helically welded perforated tubes in Stainless Steel

Structure: Perforated Tubes / Spiral wound welding

Material : SS 316L and SS 304L

Punching pattern: R3T5 (Round hole diameter: 0.125 on 0.1875 triangular pitch)

Raw material cerificate 3.1 according to EN 10204

Supply to Middle East:

Raw material from Japan, Korea

Raw material cerificate 3.1 according to EN 10204 complying with Nace MR 0175 and IGC test according to ASTM A262 Practice E.

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen