Bag Filters - Filter Bag of Micro Fiber Fabric, Non Woven PP Needle Felt with PETE Memebrane

Bag filters are made of micro synthetic fiber fabric as filter membrane, framed mostly, used in dust control in air handling systems.

Bag filters are made of micro synthetic fiber fabric as filter membrane, framed mostly, used in dust control in air handling systems.

Bag Filters General Description:

1. Media: Fiberglass, synthetic fiber(PP, etc.)

1. Media: Fiberglass, synthetic fiber(PP, etc.)

2. Frame: Aluminum

3. Efficiency range from : F5,F6,F7,F8 (EN 779)

4. Average Efficiency: 45%,65%,85%,95%

5. Initial resistance: 45 Pa

6. Recommended final pressure drop : 400Pa

7. Humidity resistance: 100%

8. Max Temperature: 80 °C

9. Media color available: White,Green,Pink,Yellow

10. Filter standard depth available:

15 inch (381mm), 20inch(500mm), 24 inch(600mm)

Applications:

Bag filters are mainly used as the fine filtration elements in air handling systems and units in commercial buildings, hospitals, and computer and telephone centers, optical, fine mechanical,electronic and pharmaceutical, manufacturing plants.

Bag Filter Advantages:

1. Ensure a long operation reliability and high dust holding capacity.

2. Low initial pressure drop,high efficiency.

3. Catch the fine dust and microorganism efficiently.

4. Offer different pocket number design to meet different airflow requirements.

Choose Bag Filters according to filtration efficiency /Filter Classes:

F5 to F8 fine filters can be used as the pre-filters for HEPA filter.

F5, F6 is mainly for the ventilation system for comfortable air supply for office or building.

F7 is to prevent the specks engender in the air supply ceiling of hotels.

F8 can be used as the final filters for 300,000 class clean room.

| Model | Size | Technical Specification | Material | |||||

| W*H*T (MM) | No. Of bags | Area of net media (M2) | Rated airflow m3/h | Efficiency / Initial resistant% / Pa) | Membrane | |||

| DG-01 | 592*592*650 | 10 | 8.1 | 3600 | 65/70 | 85/95 | 95/130 | Microfiber |

| DG-02 | 592*592*650 | 8 | 6.6 | 3600 | 65/80 | 85/110 | 95/150 | Microfiber |

| DG-03 | 592*592*550 | 8 | 5.6 | 3600 | 65/85 | 85/115 | 95/155 | Microfiber |

| DG-04 | 287*592*650 | 5 | 4.1 | 1800 | 65/70 | 85/95 | 95/130 | Microfiber |

| DG-05 | 287*592*650 | 4 | 3.3 | 1800 | 65/80 | 85/100 | 95/150 | Microfiber |

| DG-06 | 287*592*550 | 4 | 2.8 | 1800 | 65/85 | 85/115 | 95/155 | Microfiber |

| DG-07 | 490*592*650 | 8 | 6.5 | 3000 | 65/70 | 85/95 | 95/130 | Microfiber |

| DG-08 | 490*592*650 | 6 | 5.0 | 3000 | 65/80 | 85/110 | 95/150 | Microfiber |

| DG-09 | 490*592*550 | 6 | 4.2 | 3000 | 65/85 | 85/115 | 95/155 | Microfiber |

Non-woven Cloth Bag Air Filter 592×592 MM

Non Woven Cloth Bag Filter is mainly used for filtering dust particles greater than or equal to 5μm in air conditioning systems to protect the secondary filter and prolong its service life. The secondary bag air filter is mainly used for filtering dust particles greater than or equal to 1μm in air conditioning systems to protect the sub-high efficiency or high-efficiency filter after it and prolong its service life.

Non Woven Cloth Bag Filter is mainly used for filtering dust particles greater than or equal to 5μm in air conditioning systems to protect the secondary filter and prolong its service life. The secondary bag air filter is mainly used for filtering dust particles greater than or equal to 1μm in air conditioning systems to protect the sub-high efficiency or high-efficiency filter after it and prolong its service life.

Bag type air filter dimension 592×592. Supplied with 3~12 parallel bags.

Bag depth of different bag filters vary within 250~900mm.

According to different filter performance requirements, multi-layer compound synthetic fiber drum material, synthetic fiber nonwoven cloth of different thickness or glass fiber can be adopted as the filter materials of the bag filter. The bag is provided with separation grids, which can effectively improve filtration area of bags.

Features:

1.Applicable for common air conditioning system

2.Filter media made of non-woven cloth

3.Filer Frame: Aluminum, Galvanized Steel is also available

4.Mini. 90% average efficiency of fiber media

5.Common size 592x592x600mm, any size available

Filter Bag PP Needle Felt with PETE Memebrane

Filter Bag

Material: PP Needle Felt With PTFE Membrane

Diameter: 130 mm, Length: 2520 mm

Application: Powder Silo Filter Part

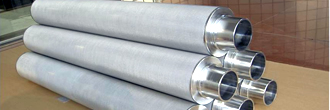

Basket Strainer Diameter 122 X Length 3000mm

Basket strainer for Application: Bag Filter

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen