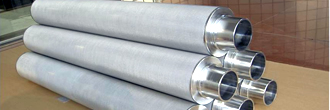

Air Filter Cartridge Element-Cylindrical and Conical Air Filter Elements for Power Stations, Automotive and Machinery

Air Filter Cartridge Elements we supply can be devided into mainly three types according to applications: Air Compressor Filters, HVAC Air Filters, Automotive Air Filters. According to filter material, air cartridge filters can be made of Synthetic, Sintered Metal or Metal Mesh. Made of various filter media and supporting metal mesh. Replacable.

Air Filter Cartridge is designed to fit into a filter housing or compartment. Featuring pleated or wound filtration media, cartridge air filter element provides a larger surface area for trapping contaminants for high-flow, heavy-duty applications.

Air Filter Cartridge Elements Types According to Uses:

Cartridge air filter elements are mainly used for Industrial applications, gas turbines, engines, HVAC systems and air purifiers. Especially:

Industrial Air Filter system for manufacturing plants, air compressors, and pneumatic systems;

HVAC Air Filters for heating, ventilation, and air conditioning systems;

Automotive Air Filters System for engines of vehicles, trucks, and motorcycles.

Cartridge Air Filter Elements

Air Compressor Filter Cartridge

Air filter cartridges designed for inlet filters of steam turbine engines and centrifugal air compressor.

Features: High efficiency, low resistance, high reliability, longlife and anti-mist.

Air compressor filter elements consist of a reinforced polyester or fiber media bonded to an expanded metal support mesh grid. Filter media: Pleated filter media increasing the Filtration surface area to 3 times that of the face area.

Material :

Cover: Steel Galvanized, Aluminum, Plastic

Filter Support Grid: Steel mesh expanded, plastic mesh optional

Filter Media: Polyester fabric, felt, nylon, or other synthetic fiber materials, fiberglass, activated carbon

End Caps: Metal steel, aluminum, plastic

Seals / Gaskets: Rubber, silicone

Overall Construction: Pleated to maximize surface area, with an internal support core to ensure integrity under high pressure.

Standard Specifications:

| Model | Outer diameter (mm) |

Inner diameter (mm) |

Height (mm) |

Crank Rod Hole (mm) |

Net media (m2) |

Air flow(m3/h) | |

| Rated | Ranged | ||||||

| HM3266/27 | Φ324 | Φ212 | 660 | Φ27.5 | 21.2 | 1000 | 800-1500 |

| HM3256/29 | Φ324 | Φ212 | 559 | Φ29.5 | 18.0 | 850 | 700-1300 |

| HM3286/27 | Φ324 | Φ212 | 864 | Φ27.5 | 27.9 | 1300 | 1000-2000 |

| HM3288/29 | Φ324 | Φ212 | 876 | Φ29.5 | 28.2 | 1350 | 1000-2000 |

| HM3270/27 | Φ324 | Φ212 | 700 | Φ27.5 | 22.5 | 1050 | 800-1600 |

| HM3261/27 | Φ324 | Φ212 | 610 | Φ27.5 | 19.6 | 900 | 700-1400 |

| HM3250/27 | Φ324 | Φ212 | 500 | Φ27.5 | 16.1 | 750 | 600-1100 |

| HM4091/13 | Φ405 | Φ291 | 915 | Φ13.5 | 38.0 | 1800 | 1400-2700 |

| HM4056/27 | Φ405 | Φ291 | 559 | Φ27.5 | 23.2 | 1100 | 800-1600 |

| HM3571/27 | Φ352 | Φ240 | 711 | Φ27.5 | 25.6 | 1200 | 900-1800 |

| HM3246/29 | Φ307 | Φ195 | 460 | Φ29.5 | 13.8 | 650 | 500-1000 |

Cylindrical Air Element Filters for Air Intaking

Technical specifications for air element filter for air intake of gas turbine

Filter shape: Cylinder shape

Size of filter:

Length : 660 mm

Outside diameter : 322 324 mm

Inside diameter : 211 213 mm

Media type: Cellulose = 80 % & Polyester = 20 %

Design air flow for one set ( 1set = 1152 element ) = 360 m³/ sec

Grammage = 130 gr/m²

Filtration area = 21 m²

Mean pore size: ( max ) 52 micron

Dust Holding Capacity = 3500 g

Work properly in desert dusty and fog atmospheres

Hole of end cap: 30 mm ±1 mm

Permeability at 200 pa 140 ± 20 L/SEC/M²

Pressure drop: Initial Resistance pressure 20 38 mm wc,

Final Resistance pressure 130 mm wc

Efficiency: Standard coarse AC test dust 99.94 %,

Standard fine AC test dust 99.60 %

Element life: Shelf life 3 years

Operation life: 24 month

Operating relative humidity ( MAX ): 100 %

Operating temperature: 66 Cº

Titanium Powder Sintered Porous Titanium Car Air Filter

| Item Name | Sintered Cartridge Filter |

| Porosity | 28%-50% |

| Aperture | 4μ-160μ |

| Filtration precision | 0.2μm-100μm |

| Filtration Efficiency | 98% filtration accuracy under:0.1 - 80um |

| Shape | Disc,squareness,tubular,rodlike |

| Work environment | Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, hydrogen, nitrogen, hydrogen sulfide, acetylene, water vapor, hydrogen, gas, carbon dioxide gas environment |

Technical parameters( Allow ≤250°C the conditions of using)

| Filtering level | Filtering precision (μm) |

Maximum Aperture (μm) |

Permeability (m3/h.m2.kpa) |

Thickness (mm) |

Compressive strength (Mpa/cm2) |

| T9 | 0.2 | 2.5 | 1.5 | 3 | 3 |

| T8 | 0.5 | 4 | 3 | 3 | 3 |

| T7 | 1 | 6 | 5 | 3 | 3 |

| T6 | 2 | 10 | 15 | 3 | 3 |

| T5 | 5 | 15 | 40 | 3 | 2.5 |

| T4 | 10 | 30 | 120 | 3 | 2.5 |

| T3 | 20 | 60 | 250 | 3 | 2.5 |

| T2 | 30 | 100 | 500 | 3 | 2.5 |

| T1 | 50 | 160 | 800 | 3 | 2.5 |

Cylindrical Air Filter Element

Shape: Cylindrical

Cylinder size: 150 x 50 x 4.5 CM

Mat. Big Syntetic Fiber

Application: Designed for Seal Air Fan HRSG & Generator GT

Cylindrical & Conical Air Filter For Power Station Gas Turbine and Generator

Description of Gas Turbine below:

| Generator Unit Type | EFLA-K |

| Gas turbine Model Series (GE Design) | MS-6001 B |

| No. of turbine stages | 3 |

| No. of Compressor stages | 17 (Axial) |

| Base Output | 35700 KW At 40°C Peak load, |

| Type of Operation | Continuous |

| Compressor Inlet Temperature | 35°C |

| Turbine Exhaust Temperature | 551°C |

| Control | Mark-vi Speedtronic |

Unit, Place and condition where air filter to be used:

| Unit: | 100MW, PG 9171 E, GE ENERGY PRODUCTS- EUROPE |

| Total air flow of the unit (ton/hr): | 1458 Ton/Hr |

| Total filtration area: | For turbine: 1900 Sq. ft. For Generator: 317 Sq. ft. |

| Temperature range: | +05 to +45 °C |

| Weather Condition: | Tropical High humidity (90%) Rainy, Dirty, Foggy & Dusty Ground, Insects, Flies & Mosquitoes. |

| Place of Use: | Turbine & Generator Intake |

| Type of Filter: | Pulse - cleaning filter (cylindrical & conical) |

| Number of stages: | Single stage |

| Type of dust: | Dry, Moisture, corrosive Sooty-Oily & Erosive. |

Air Filters comply with following Technical Specifications:

Cylindrical & Conical Filter:

| Item | Specification | |||||

| Filter Media | Synthetic | |||||

| Filter Media Grade | FA-301/EN 7.1.301. | |||||

| Thickness | 0.013 Inch | |||||

| End Cap Material | Galvanized G.l. Sheet (SPGP) with Filter Media potted in Plastisol to ensure leak free seal. | |||||

| Element Shape | Cylinder | |||||

| Cone | ||||||

| Size | Dimension: | Large end(OD) |

Small end(OD) |

Length | ID | |

| Cylinder: | 324mm | 324mm | 660mm | 212mm | ||

| Cone: | 445mm | 324mm | 660mm | 331/213mm | ||

| Air Flow Capacity | For Cylindrical: Max. 650 CFM & for Conical: Max. 850 CFM. | |||||

| Initial Pressure Drop | 1.0" W.C. across the Filter Element. | |||||

| Collapse Pressure | 30" W.C. | |||||

| Bust Strength | 25 psi | |||||

| SAE fine dust holding capacity | 4940 gms at 4" W.C. | |||||

Test results comply with the following Test result.

| Pleat Depth | 50 mm + 1.0 mm | ||

| No. of Pleats | 300 + 2 inch deep pleats held in place with Rotary Pleater for Cylindrical air filter, 355 + 2 deep pleats held in place with Rotary Pleater for Conical filter. | ||

| Gasket Materials | Seamless Polyurethane | ||

| Gasket Size | Filter Type | Cylindrical | Conical |

| Inner Diameter | 257.14 mm | 405/222 mm | |

| Outer Diameter | 276.46 mm | 420/241 mm | |

| Height | 12.7 mm | 12.7 mm | |

| Liners | Galvanized expanded metal with 72% open area. | ||

| Spiral Beading on Filter Elements. | Filter media with liners are fixed with Hot melt spiral beading on inside & outside of filter elements to ensure rigidity & media pack geometry. | ||

| Count Efficiency | 99.99+% on 0.44 micron & larger particles. | ||

HEPA Air Purifier Filter Cartridge - HEPA (High-Efficiency Particulate Air) Filter

Features:

1) Highly effective, low density virgin carbon.

2) Machine packed carbon enables 100% filtered air flow.

3) Inner and outer mesh provides 53% open area allowing increased air flow.

4) Includes changeable Velcro pre-filter.

5) Switchable filter flange and base for longer lifetime.

6) Large selection of sizes available to fit any application.

Features:

1.G4 Coarse air filter is available in efficiency of 90% on 5 micron particles;

2.Large air flow;

3.Low resistance;

4.High dust holding capacity;

5.Long service life;

6.Used as first stage filters in air condition system and as prefilters in multilevel filtering system.

Advantages:

The filter core consists of a reinforced polyester fiber media bonded to an expanded metal support grid which is then Pleated, increasing the Filtration surface area to 3 times that of the face area. These series have such features as available in efficiency of 90% on 5 micron particles, large airflow, low resistance, high dust holding capacity, reasonable price and low cost

Applications:

1. usable for primary filtration of the ventilation system

2. electronic,food and industry

3. Used as first stage filters in air condition system and as pre filters in multilevel filtering system.

| Frame Material | Aluminum |

| Filter medium | Filter cotton |

| protect nets | Expanded Aluminum nets |

| Max. temperature | 80°C |

| Max. humidity | 80%RH |

Products List

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen

Wedge Wire Screen

500 Micron Wedge Wire Cartridge

Wedge Wire Basket Filter Elements

SS316L Wedge Wire Screen Filter

Wedge Wire Element

Basket Filter Element

Slotted Liner

Perforated Disc

Sand Filter Screen

316L Wire Wrap Slotted Screen

Vibrating Screen Mesh

Dutch Weave Wire Mesh Filters

Extruded Screen

Black Steel Circular Extruder Screen

Mild Steel Filter Screen

Stainless Steel Wire Mesh Belt Filter Screen

Monel Mesh Filter

904L Dutch Weave Filter Screen

Screen Filter for Film Making

Basket Strainer Element

Coalescer Filter Elements

Granulator Filter Mesh

Cone Filter Element

Stainless Steel Mesh Filter Screen

Surface Filter Element

Sintered Fiber Pleated Filter

Stainless Steel Wedge Wire Water Well Screen