Stainless Steel Wedge Wire Water Well Screen

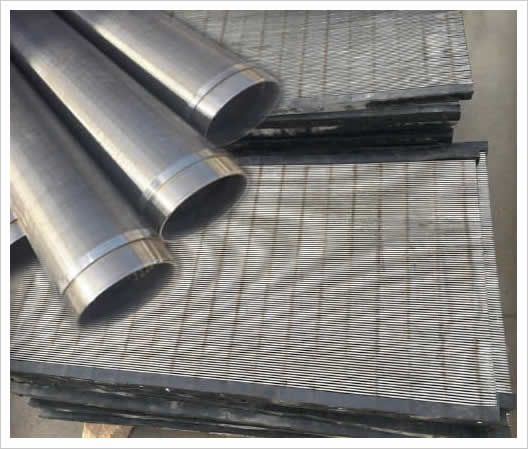

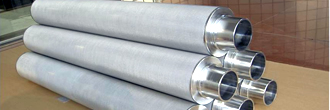

Wire wrapped stainless water well screen is made by a v or wedge profile wire around an internal array of longitudinal support rods. Each intersecting point of these wire is fusion welded to form a precise and uniform mesh. Wedgewire profile screen combines superior weld strengths with accurate slots tolerances resulting in a reliable sand control screen applied in well drilling industries. Our stainless steel well screen offers stable structure and good strength, can withstand the pressure and corrosion during the downhole well completion and operation.

Pipe Screening Construction Structure:

Well Processing Sand Control Mesh Screen Pipe has a continuous non-clogging slot opening: It is constructed with a continuous “V” shaped wire wrapped around, approximately triangular in cross section, around a circular array of the longitudinal rods. Then the wire welded to, perpendicular support rods with a specific slot opening. Thus producing rigid one-piece units having high strength characteristics at minimum weights. This design allows free flow and high intake efficiency.

Stainless Steel water well screen is also a pipe base filter cylinder. The tube screens are used for deep wells with stand-alone completions, also used in combination with gravel pack completions.

Well screens are completed with stainless steel fittings including end plates, weld rings, flush joints and NPT threaded joints on the screens.

Stainless Steel Mesh Screen Specifications:

We offer general filtration and heavy duty metal mesh screens for filtration and separation applications in Water, Oil / Gas, Geothermal, Petrochemical, General Filtration Industries and Environmental Monitoring.

Materials: Grades of simple stainless steel 304, 316, 304L right up to highly corrosion resistant alloys.

Slot opening: Slot should be bigger than 0.020mm and less that 2500mm long.

Wire shapes and sizes: Custom

Combination of wire and rods: Available to meet the open area and strength requirements for the particular application.

Technical data of 304 316Lstainless steel wedge wire screen

| No. | (mm)TYPE | OD (mm) | ID (mm) | Support wire Number | Filter direction |

| 1 | SRD25.4 | 25.4 | 18.6 | 12 | FOTI |

| 2 | SRD 33 | 33 | 24 | 8 | FOTI |

| 3 | SRD 37 | 37 | 28 | 8 | FOTI |

| 4 | SRD 40 | 40 | 31 | 8/10 | FOTI/FITO |

| 5 | SRD 45 | 45 | 36 | 10/12 | FOTI/FITO |

| 6 | SRD 48 | 48 | 38 | 12 | FOTI/FITO |

| 7 | SRD 60 | 60 | 51 | 12 | FOTI/FITO |

| 8 | SRD 70 | 70 | 61 | 12/18 | FOTI/FITO |

| 9 | SRD 85 | 85 | 76 | 18 | FOTI/FITO |

| 10 | SRD 110 | 110 | 101 | 24 | FOTI/FITO |

| 11 | SRD120 | 120 | 111 | 24 | FOTI/FITO |

Stainless Steel Profile Wire Well Screen Constructed with Continuous Slot Opening and Large Open Area, Providing Greater Water In-taking Efficiency

Non Clogging V Wire Pipe Base Screen ensures an uninterrupted free flow and an effective sand control.

Benefits:

1. Screens with high open area a suitable for the construction of high-quality water wells, oil wells and gas wells.

2. Low cost operation Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water level’s down, thus to save energy consumption.

3. Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwater’s entering into the screen much slower than any other filtration apparatus, which will avoid sand’s entering into screen because of high pressure, thus reduce the abrasion of the pump.

4. Extend the life span of wells

Comparatively, groundwater’s entering into screen with higher open area is much easier than the entering into lower open area screen. The slow water flow shall extend the life span of wells.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen