Stainless Steel Perforated Filter Basket - Filter Elements Manufactured from Perforated Stainless Steel Sheet

Perforated stainless steel basket type filter elements have two types according to the filter media: one is Perforated Metal Basket, the other is Perforated Basket filled with Woven Filter Wire Cloth Layer. The stainless steel basket filters are mainly used for the filtration of air, the medium cleaning and flow control of lubrication oil, hydraulic pressure and air pressure system.

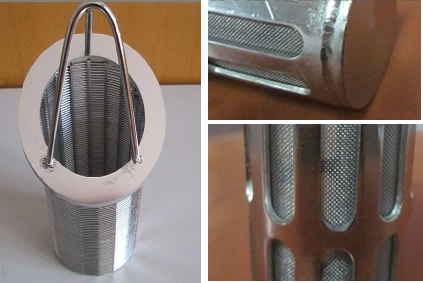

Perforated Metal Filter Basket with Woven Wire Cloth Filter Layer

Filter basket is used for the filtration of air, the medium cleaning and flow control of lubrication oil, hydraulic pressure.

The stainless steel filter basket is made of woven wire cloth and perforated metal sheet.

Structure:

One layer with woven wire cloth inside to control the filter rating and one layer of perforated metal outside as support sheet. The two layers are welded with the top and bottom. The perforated metal layers are processed from large opening oblong slotted stainless steel plates.

Filter Screen for Basket Strainer

Inner filters basket strainer with 2 layer SS2205

Inner layer perforated screen: Peforeted SS2205 with 1/8inch holes, thickness: 1mm

Inside layer wire cloth: 2205 wire mesh (40 mesh)

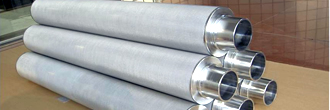

stainless steel Perforated Round Hole Sheet Welded Tube Processed basket filter element

This type of filter element is made of pure perforated metal sheet cut and welded into cylindrical tube forms. The perforated sheet materials are popularly stainless steel sheet punched with round openings. Fixed to the bottom and top rims. With or without handles.

Perforated metal basket filter element features rigid structure and easy cleaning.

Application: Widely used in chemical industry, chemical fiber, food and beverage, medicine, papermaking, environmental protection, the manufacturing of machinery, electric power, electron, metallurgy, lubricating oil, involving the hydraulic oil, etc, water, coating, paint, filtering processing industries.

Main Features:

1. Simple structure and easy installation;

2. High porosity, good permeability, good flow velocity, easy cleaning;

3. High intensity, long service life, excellent corrosion resistance, wide temperature range of uses;

4. Economic cost;

5. Rigid structure with uniform opening.

Well sold basket filter product:

Filter elements of perforated stainless steel sheet

Elements with 200 mesh size (75 micron aperture).

Elements with threaded ends

Cylinder width 10mm and length 100mm

Specifications of Perforated Filter Basket:

| Item | Model | Nominal flow rate (L/min) | Filter precision (mesh) | Nominal pressure (MPa) | Pressure loss (MPa) | Size (mm) | ||

| Initial | Max | D | L | |||||

| Basket Filter Element | SZG-60 | 60 | 60 80 100 150 | 1.0 | No more than 0.1 | 0.35 | 100 | 200 |

| SZG-100 | 100 | 150 | 250 | |||||

| SZG-150 | 150 | 180 | 300 | |||||

| SZG-200 | 200 | 240 | 380 | |||||

| SZG-250 | 250 | 240 | 450 | |||||

| SZG-300 | 300 | 300 | 450 | |||||

Perforated metal strainer baskets

Perforated SS Strainer Basket

Perforation size: 1/4" 2.

Bottom diameter:1-3/4" 3.

Height of basket: 4" 4.

Height overall: 8" 5.

Diameter across flange: 2-1/4" 6.

Top diameter: 1-3/4"

Basket for food strainer application

Stainless steel perforated filter basket

Shape: Rectangular

Size: 300 mm x 235mm x 85 mm

Holes: 2mm

Perforated Metal Mesh Tubular Strainers

Mesh net: Open area 0,66 mm.

Wire diam. 0,40 mm, max. 0.50mm

Length: 119 mm.

Tube strainer is open in both ends

Sea Water Strainer, Made of Perforated Metal Sheet

Material: SUS304

Thickness: 3mm and above

Hole diameter: 4mm

Pitch: 6mm

Perforated metal water strainer

SS304 Perforated Filter Elements - Basket Strainer

Perforated

sheet hole 1.5 mm * 1 mm thickness

For basket strainer,10 , 150

ASTM A105 body and flange, RF, sch./40, 304 stainsless steel basket

1/16 perforrated basket bolted hlind flange, NPT vent and drain 1

Stainless Steel Strainer

Raw milk inline Stainless steel strainer with single layer

Perforated Size: Length: 356mm

Internal diameter: 38mm

Open on both end.

3 layered perforated for pasteurizerLength: 495mm

Internal diameter: 38mm

Tube end thickness: 2mm

Closed on one end.

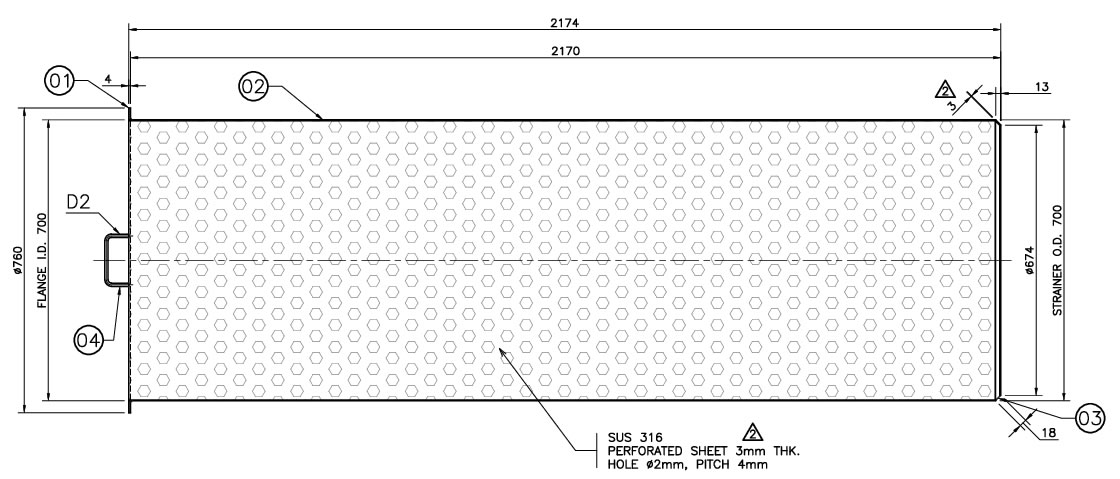

Stainless Steel Filter Basket

Perforated plate thickness from 2mm to 3mm, as per users request

Perforated plate pitch, from 3mm to 4mm

Filter strainer with flange

All welds shall be fillet weld wherever possible double fillet, size 0.7 x minimum thickness of the plate being welded.

Filter Strainer Size: 700 dia x 2174 mm long

Micron : 2000 micron

Material : SS316

Perforated Sheet Thickness: 3 mm

Hole size: 2 mm

Pitch : 4mm

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen