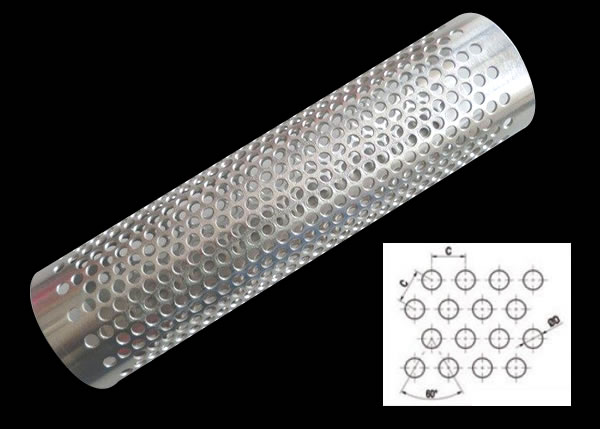

Perforated Tube for Filters: Filter Support Core, Protection Sleeve

Perforated metal tube Hole Patterns including: Round; Rectangular hole; Square; Triangle; Diamond; Hexagonal; Cross; Slotted; and other patterns according to your drawings or application requirement.

Hengmao offers choice perforated metal tubes used for manufacture of pleated filters and wound filters. Mainly Stainless Steel Perforated Tubes for Mechanical and Structural Support of the Pleated Filter Elements.

Using of the metal support layer, as core of the filter or surface screen, the filter elements will have a good strength and an extended service life.

Popularly, we use round hole and square hole perforated sheet for processing of filter tubes. Custom designs of perforated filter support tubes available.

Perforated metal tube Hole Patterns including: Round; Rectangular hole; Square; Triangle; Diamond; Hexagonal; Cross; Slotted; and other patterns according to your drawings or application requirement.

Features:

Can be readily formed

Can be polished

Easy installation

Uniform opening and uniform strength

Wide range of thickness available

Large selection of hole size pattern and configurations

Superior abrasion resistance

Accuracy of size

Applications: Perforated metal sheets are cut and welded into tubes. Widely used in the core of filter or the surface of the pleated filter elements, filter screen, strainers.

Thickness or Gauge of Stainless steel Perforated Tube:Thickness of the metal sheets do not change during the perforation. Normally thickness is expressed in gauge, please see the picture. However, to avoid possible misunderstanding, we would suggest to express them in inches or millimeters.

Diameter and Length of Stainless steel perforated metal tube

Diameter:10mm,15mm,20mm,25mm,30mm,35mm,500mm,etc

Length: 50mm,100mm,200mm,500mm,1200mm, or custom

Margins of Stainless steel perforated tube: Margins are the blank (un-perforated) area along the edges of the sheet. Normally the margin on the length are 20mm minimum, and margin along the width can be 0 minimum, or at clients' requests.

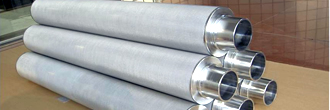

Stainless Steel Perforated Filter Tube Cores for Pleated Filter Elements

Tubular Filter Support Core

Cores for pleated filters

Material:Stainless steel cores for water filter cartridges.

Tubular core size: Length 248mm, 498mm, 748mm

Inner diameter of the tube: 31mm x thickness 0.5mm

Stainless Steel Perforated Tube Cores for Tubular and Basket Filter Elements

Filter Tube Perforated for Wire Cloth Strainer

Tube or pipe type element filter, Ø72 mm x length 161 mm

Structure made in UNS S32760 with perforated plate

Tube thickness 1,5 mm, perforated hole size 3 mm

Screen mesh 80

Perforated Tube Cores for Wound Filters

Perforated metal filter element cores are used in various filtration applications, particularly in liquid filtration systems. These cores typically consist of a perforated metal tube around which a filtering material (often a wound wire or a yarn-like material) is wound. The perforated core serves as the structural backbone for the wound material and also facilitates the flow of liquid through the filter.

Features of perforated metal filter cores for wound filters:

-

High Strength: The metal core provides mechanical strength, enabling the filter to withstand high pressure and mechanical stress.

-

Flow Rate: The perforation pattern can be designed to facilitate desired flow rates.

-

Compatibility: Made from materials like stainless steel, these cores are compatible with a wide range of chemicals and temperatures.

-

Reusability: The metal core can often be reused after cleaning, making it a more sustainable option compared to disposable filters.

-

Customization: The size, shape, and perforation pattern can be customized according to application requirements.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen