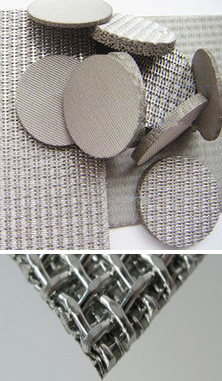

Vacuum Sintered Wire Mesh Laminated Sheet - - Single Layer, 2, 3, 5, 6 Layer Available - in Stainless Steel and Alloy Metals

Hengmao offers rigid laminated filter sheet of sintered wire mesh multi-layer made of stainless steel and alloy metals. Suitable for processing of filter discs and filter cylinders / tubes. Single layer of woven wire mesh, double layer, three layer, five layer or six layer sheets. With woven wire cloth of various apertures, or with perforated metal sheets sintered together into porous structures. Accurate filter rating available.

Multi Layer Sintered Wire Mesh Sheet

Technical Processing of Sintered Wire Mesh:

Sintered wire mesh is produced by a series of technical processes. Precision woven wire mesh is uniformly calendered (roller flattened) to ensure good contact at the wire cross over points. One or more layers of this calendered mesh are then laminated under mechanical pressure in special fixtures inside a high temperature furnace. This furnace is filled with a proprietary inert gas atmosphere and the temperature is raised to a point where sintering (diffusion bonding) occurs. After controlled cooling, the mesh has now become rigid by the bonding of the individual wires to each other and of each layer to the adjacent layer. Its comprehensive property is superior to sintered metal powder.

Material: Woven wire mesh, perforated metal from material of stainless steel, brass, aluminum,etc.

Types: single-layer and multi-layer.

Filter rating: Minimum filter rating: 3 micron

Any outline size and filtration rating available as the requirements of the customer.

Applications: Sintered metal mesh filter cartridge is mainly used for the filtration of air, the medium cleaning and flow control of lubrication oil, hydraulic pressure and air pressure system.

Multi layer sintered wire mesh can be processed into following forms:

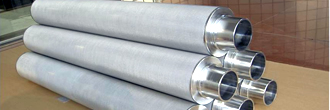

1.Cylindrical Filter Element

It is widely applied in the filtration of liquid and gas. And it is applied in many industries, such as petrifaction, polyester, pharmacy, food and beverage and water treatment.

2.Filter Disc

It is mainly applied in drying and filtration in the

pharmacy industry. The minimum diameter we can process can be up to 3000mm. And we can process it in

split and integral type dynamic filter elements with effective filtration and separation. It is mainly used in chemical, pharmaceutical and beverage industries.

Sintered Woven Wire Mesh Common Specification:

1.Micron: 3-300um

2. Max Size:1200*1000*1.7(+-0.2)mm

3. Standard Size:600*1200*1.7(+-0.2)mm,500*1000*1.7(+-0.2)mm

4. Common Materials:AISI(SUS)304,316,316L

5. Layers: 3,4,5,6,7,8 and etc

Why Sintered Woven Wire Mesh?

By combining muliti layers of different wire meshes, it is possible to design materials with specific target thickness, permeability, pore size, and mechanical strength.

Some layers are used for high precision filtration, others for protecting and reinforcing.

Comparing with woven wire mesh non sintered, sintered wire mesh as filter media offers rigid structure and accurate rating. The disadvantage is the sitnered mesh cost higher than woven wire mesh.

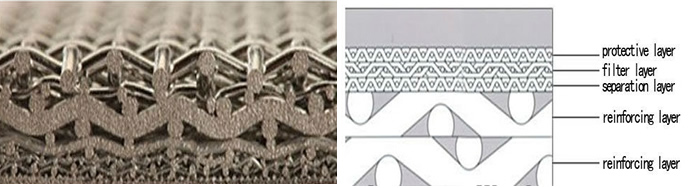

5 Layer sintered Stainless Steel Wire mesh - SS Sintered mesh Available in other Layer Options

5 lays sintered mesh is overlapped and stacked up by 5 layers of plain dutch woven wire mesh

with various hole size, after vacuum sintering, pressurizing and rolling. It has the average pore size and steady air permeability.

Dutch woven sintered wire mesh can be widely used in powder transport, laboratory fluid bed, driers and coolers.

Typical five layer sintered wire mesh sheets have the following functional layers:

1.Reinforcing layer;

2. Reinforcing layer;

3. Separation layer;

4. Filter layer or control layer;

5. Protection layer.

This sintered mesh sheet offering following features:

*Filtration ratings: 1u to 200u

*Stable precision: Two protection layer,stable mesh makes stable precision available

*Thermostability: withstand 480°C high temperature

*Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

*corrosion- resistant material: SUS316L,SUS304

*Standard size:500mm×1000mm 600mm×1200mm 1000mm×1200mm, 1000 x 1000 mm.

Various specifications are available as request.

5-layer sintered wire mesh technical specification list:

| Model | Nominal Filter Rating ( u) | Structure | Thickness (mm) |

Air Permeability (L/min/cm2) | Bubble Pressure (mm H2O) | Weight (kg/sqm) | Porosity (%) |

| SM5-1 | 1 | 100 + 400 × 2800 + 100 + 12 × 64 + 64 × 12 | 1.7 | 1.81 | 360-600 | 5-layer sintered wire mesh(8.4)

6-layer sintered wire mesh (14.4) |

37% |

| SM5-2 | 2 | 100 + 325 × 2300 + 100 + 12 × 64 + 64 × 12 | 1.7 | 2.35 | 300-590 | ||

| SM5-5 | 5 | 100 + 200 × 1400 + 100 + 12 × 64 + 64 × 12 | 1.7 | 2.42 | 260-550 | ||

| SM5-10 | 10 | 100 + 165 × 1400 + 100 + 12 × 64 + 64 × 12 | 1.7 | 3.00 | 220-500 | ||

| SM5-15 | 15 | 100 + 165 × 1200 + 100 + 12 × 64 + 64 × 12 | 1.7 | 3.41 | 200-480 | ||

| SM5-20 | 20 | 100 + 165 × 800 + 100 + 12 × 64 + 64 × 12 | 1.7 | 4.50 | 170-450 | ||

| SM5-25 | 25 | 100 + 165 × 600 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.12 | 150-410 | ||

| SM5-30 | 30 | 100 + 450 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.7 | 120-390 | ||

| SM5-40 | 40 | 100 + 325 + 100 + 12 × 64 + 64 × 12 | 1.7 | 6.86 | 100-350 | ||

| SM5-50 | 50 | 100 + 250 + 100 + 12 × 64 + 64 × 12 | 1.7 | 8.41 | 90-300 | ||

| SM5-75 | 75 | 100 + 200 + 100 + 12 × 64 + 64 × 12 | 1.7 | 8.7 | 80-250 | ||

| SM5-100 | 100 | 100 + 150 + 100 + 12 × 64 + 64 × 12 | 1.7 | 9.1 | 70-190 |

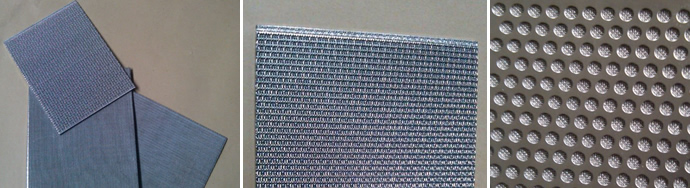

Sintered Woven filter mesh Reinforced with Perforated Metal Laminated Sheet

This metal laminated sheet is sintered with punching plate and multi-layer stainless steel wire mesh. Due to the support of punching plate, it has the higher compressive and mechanical strength. It is mainly used in food, beverage, water treatment, dust removing, pharmaceutical, polymer, etc. It can be processed into various filters: tube, disc and sheet. The thickness of the filter cloth and the structure of the sheet filter cloth be customized according to the user's requirements.

Specification of Laminated Metal Sheet Reinforced with Perforated Stainless Steel Plate:

| Modal | Pore sizeμm | Bubble-pointPressure≥Pa | Permeability(N2) | Porosity≥% | TensileStrength≥MPa | |

| L/min cm2.pa | M3 | |||||

| SSW-003 | 3 | 11200 | 8.0×10-5 | 9.1×10-13 | 35 | 90 |

| SSW-005 | 5 | 8800 | 1.0×10-4 | 2.2×10-12 | 35 | 100 |

| SSW-010 | 10 | 3860 | 5.0×10-4 | 4.8×10-12 | 24 | 100 |

| SSW-020 | 20 | 1970 | 1.0×10-3 | 1.5×10-11 | 24 | 100 |

| SSW-030 | 30 | 1350 | 3.0×10-3 | 2.2×10-11 | 26 | 100 |

| SSW-50 | 50 | 1030 | 5.0×10-3 | 4.0×10-11 | 33 | 110 |

| SSW-80 | 80 | 520 | 7.0×10-3 | 1.1×10-10 | 32 | 110 |

| SSW-100 | 100 | 410 | 8.0×10-3 | 1.9×10-10 | 32 | 110 |

| SSW-150 | 150 | 280 | 1.0×10-2 | 3.6×10-10 | 37 | 110 |

| SSW-300 | 300 | 130 | 5.0×10-2 | 5.8×10-10 | 37 | 110 |

Maximum dimension of plate (without joining) 1200mm×1200mm Note of Test Standard for Sintered Mesh: 1. Detection filter precision and dirt holding capacity according to chinese standard GB/T18853-2002. 2. Detection Bubble point pressure according to chinese standard GB/T5249. 3. Detection air permeability according to chinese standard GB/T5453, pressure difference is 200 pa, medium is air. 4. Detection breaking tenacity according to chinese standard GB/T228. |

||||||

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen