Filter Cartridges for Water and Various Process Filtration Systems

Hengmao supplies the following process filter cartridges: Stainless Steel Wire Mesh Pleated Filter Cartridge, Metal Porous Filters, PP Filter and Water Filter Cartridges. Used as simplex and duplex filters for various process filtration of air, oil, gas and other fluid. Suitable for various working environment of pressure, flow rating and working temperatures.

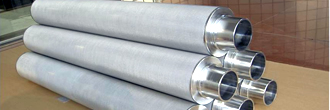

Stainless Steel Cartridge Filter Elements for Melt Spinning Process

Filter materials: Fine mesh cloth.

Fitration accuracy: from 1, 3, 6, 12, 25…… μm Filtration ratio: X≥100

Strength / pressure drop: 1.0Mpa, 2.0Mpa, 16.0Mpa, 21.0Mpa

Features

•Excellent mechanical strength

•Easily backflushed

•High flow rate

Application

•High temperature filter

•High differential pressure filtration

•High viscosity

•Corrosive fluid

Specification

•Max differential pressure:up to customer demand

•Max operating temperature: 500°C

•Media: 304SS and 316SS

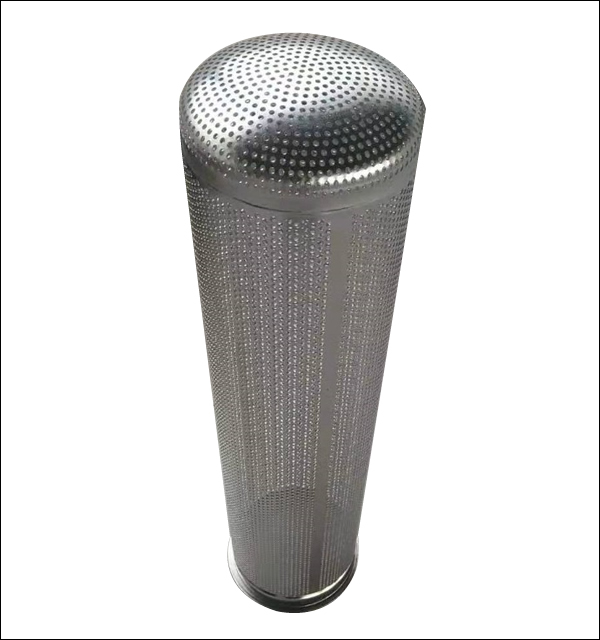

Cylindrical filter for Air Cleaning

Cylindrical Stainless Steel Cartridge

Material : SS316L

Micron rating: 74 micron

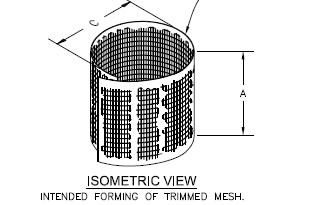

SUS304 Stainless Steel Cartridge for Filter Bag

Stainless Steel, 304 Bag Filter Housing with Cartridge Elements to suit 20000ltrs per hour at 6 Micron in apature

Size : 7” OD (17.8mmOD)

Length : 29” Length (73.6mmLength)

Hole Size : 3mm

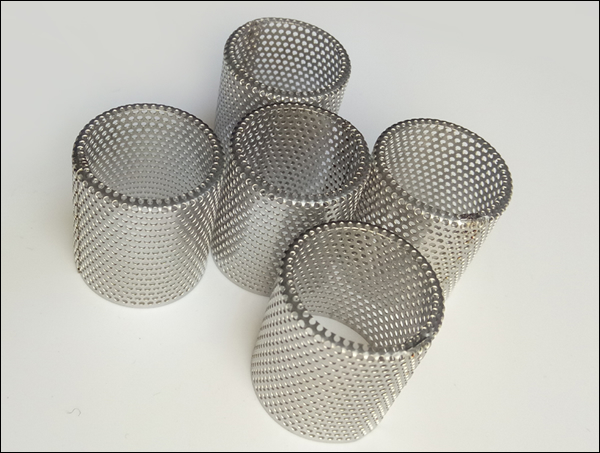

Screen filter mesh cartridge

Screen filter with top / bottom rubber gasket

Screen material: Stainless steel 304

Thickness: 8mm, or as requested.

Outside diameter: 456mm

Inner diameter: 440mm

Height: 1306

mm

Particle filtration rating: 10 micron, or as requested.

Various sizes available.

Vapor Distilled - SS Cartridge Filter - Sump Strainer

Stainless Steel Crimped Sump Strainer

Materials can be magnets or other grades

Mesh range: 30 to 200 mesh

Inner support tube: Perforated steel

Flow rate: 90-110 cfm (146-179 ft/s)

Pressure: max 1 psi

Temperature: 200C inside the filter housing

Material: T316 SS

Purpose: Prevents ground plant material from entering ethanol reservoir and “cold” section of the gas loop.

¾” SS female NPT fitting centered on bottom of filter to attach to equipment

Strainer filter connections: Steel, aluminum or nylon connection

Coupling Style

| GPM RATING | Screen Area ( Sq. inches ) | NPT ( Pipe Size) | Overall Dimensions | |

| Diameter | Length | |||

| 5 10 20 30 50 50 75 100 |

50 110 145 260 280 280 350 450 |

3/4, 1, 1-1/4 3/4, 1, 1-1/4 3/4, 1, 1-1/4 1-1/2 1-1/2 2 2-1/2 3 |

2-7/8 2-7/8 2-7/8 3-3/4 3-3/4 3-3/4 5 5 |

3-1/8 5-7/16 7-3/16 8-13/16 9-5/8 9-5/8 12-7/16 12-1/2 |

Dipple Style

| GPM RATING | Screen Area ( Sq. inches ) | NPT ( Pipe Size) | Overall Dimensions | |

| Diameter | Length | |||

| 5 10 20 30 50 50 75 100 |

50 110 145 260 280 280 350 450 |

3/4 1 1-1/4 1-1/2 1-1/2 2 2-1/2 3 |

2-7/8 2-7/8 2-7/8 3-3/4 3-3/4 3-3/4 5 5 |

3-1/2 5-3/4 7-5/16 9-5/8 9-5/8 9-5/8 12-5/8 12-5/8 |

SS304 Pleated Filters - The Process Filter Cartridge

Stainless Steel 304 Process Cartridges

Specifications

Filter Media: Woven Stainless Steel Wire Cloth

Micron Rating: 55-56 micron

Cartridge Length (Nominal): 20 inches

Cartridge Diameter (Nominal): 2.5 inches

Construction: Pleated

Element material: Stainless Steel 304

Core: Stainless Steel 304

End Cap: Stainless Steel 304

End Cap Configuration: DOE (Double End Open)

Seal Material for Gasket / O-Rings: Teflon

Cartridge Filter Area: 3.2 Sqft

Metal filter cartridges, 316L Type

Material: 316L

Internal diameters, outside diameters and lengths of the filter in mm:

- Inside 99mm

- Outside 102mm

- Length 1680 mm

- Flange outside170 mm

- 4 hole 125 mm

Permeability of filter wire in micron or mesh:

30 micron

Maximum temperature level of the environment where the filter operates:

400C

The amount of pressure on the filter (bar):

50-1100 mbar

Oil passing through the filter:

Escaid 110

With stainless steel or zinc coated steel cores inside.

Damper Bleed Cartridge

Water-pumping damper bleed and safety-screen assembly

The module consists Complete cartridge assembly with Primary Safety screens, to prevent the orifice from clogging due to particles in the water.

Cartridge Design Overview

The assembly consists of a cartridge-housing that has an outer thread of ¼ - 18 NPT and a 6mm hexsocket in one end. The cartridge-housing accepts a bleed-orifice that presses in place. This bleedorifice includes a safety screen to protect against blockage. Finally, a 10mm tubular screen fits over

the same end and is closed at one end.

Cartridge Housing:

The cartridge housing should be made from either 6061 aluminium (and anodised to protect from corrosion) or stainless steel (304/316).

The secondary screen should be pressed or bonded onto the outer shoulder of the cartridgehousing and should not be removable or easily removed

Bleed Orifice Insert & Secondary Screen:

The part includes a 0.5mm bleed orifice and is protected by an upstream 5.5mm screen with a micron

rating of 125 μm.

Primary Filter Screen:

Material: stainless 304/316

Shape: Tubular / cylinderical, circular

The primary screen should have a maximum diameter at any point of 10mm

Length of approximately 80mm

Total surface area (effective screen) should be approximately 2500mm2

The primary screen is to protect any particles from blocking the secondary screen, designed with a micron rating of < 125 μm.

The screen should have a negligible effect on flowrate when paired with the 0.5mm orifice

The screen must be rigid in nature so not to collapse as a result of pressure

This cartridge assembly includes

a. Cartridge housing

b. Bleed orifice insert (optional)

c. Primary screen

d. Secondary screen

We can supply the assembly cartridges, or supply the tubular filter screen as an individual part for our customers.

Replacement Filter Cartridge, AISI 304L, Constructed with Filter Screen 100 Mesh and Reinforcement

HM Filter Cartridge

Top: Mounting of filter cartridge, 1/2-20UNF left thread

O ring: SAE J1926-1, 1/2-20UNF left thread

Filter screen, 100mesh, seam welded cylinder / tube, DN18.5x135.5mm

Filter screen reinforcement, seam welded pipe construction, hole 1/16", DN18.5x135.5x0.5mm

Perforated plate for making reinforcing screen: 0.5mm, holes diameter 1/16", 37% open area

Material: AISI 304L

Finish: Blank, deburred, clean

Tolerance: DIN 7168 m

Stainless Steel Filter Cartridges

Stainless steel filters of 16x16 mesh and 10x10 Mesh.

Perforated metal cylinder:

18.10 and 12.10 inches tall, for 18 inches with a tolerance of ± .03

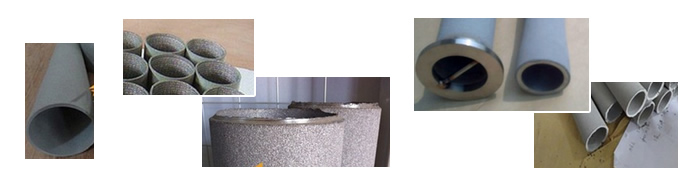

Sintered Metal Porous Filter Cartridge

| Item Name | Stainless Steel Powder Sintering Material for Filter | |

| Porosity | 28%-50% |

|

| Material | 304L,316,316L,317L,410L,430L,434L | |

| Aperture | 2.5-160μm | |

| Filtration precision | 0.2μm-80μm | |

| Filtration Efficiency | 98% filtration accuracy under:0.1 - 80 μm | |

| Compressive Strength | 3.0Mpa/cm2 | |

| Shape | Tubular, Plate, Bar, Disc, Strip and so on. | |

| Specification(mm) | Thickness | 0.5-20 |

| Width | Less than 250 | |

| Work environment | Nitric acid, sulfuric acid, acetic acid, oxalic acid, etc. | |

| Filtration Class | Filter Rating (mm) | The Max Diameter Of Hole (μm) | Permeability ( m3 / h.m2.kpa ) | Pressure-resistance (Mpa) | |

| Volume Tube Welding | Seamless Tube | ||||

| S1 | 65 | 160 | 1300 | 3 | |

| S2 | 40 | 100 | 800 | 0.3 | 3 |

| S3 | 28 | 60 | 350 | 0.3 | 3 |

| S4 | 10 | 30 | 160 | 0.3 | 3 |

| S5 | 5 | 15 | 40 | 0.3 | 3 |

| S6 | 2.5 | 10 | 10 | 3 | |

| S7 | 1.5 | 6 | 5 | 3 | |

| S8 | 0.5 | 4 | 3 | 3 | |

PP yarn wound stainless steel core filter cartridge

PP cartridge filters elements

Material: SUS304

Filter mesh type: Micron

Technical specification:

| Parameter | Unit | Specification |

| Type | Yarn wound | |

| Nominal filter rating | micron | 5.0 |

| Specific flow rate | m3/m2.h | 14 |

| Operation data: | ||

| Operating pressure | barg | 24.14 |

| Max. allowable operating pressure | barg | 32 |

| Max. operating temperature | °C | 80 |

| Differential pressure: | ||

| Initial | bar | <0.2 |

| Max. operation | bar | 1.5 |

| Dimensions: | ||

| outside diameter | mm | 63 |

| Length | mm | 1524 |

| Inside core diameter | mm | 34 |

| Area of each cartridge filter element | m2 | 0.30 |

| Total area of filters in each vessel | m2 | 42.85 |

| Material: | ||

| Yarn | PP | |

| Core | S.S | |

| Nuts | S.S | |

| Mode of installation: | ||

| Top (Threaded Type,1-5/16 11G,2 Nuts, 3mm gasket one) | Stainless steel end pipe with 1 inch pipe threaded and 2 nuts and gaskets in cartridge plate with ~ 40mm thickness and 1 washer. | |

| Bottom (Threaded Type:M8, 3 Nuts, 2 gaskets) | Closed cap with 8mm threaded bolt with 3 nuts for bracing with steel bands and 2 washer. | |

| Backwash conditions: | ||

| Air | Dry and oil free, 5.5barg pressure | |

| Water | Condensate from condensate storage tank | |

Polyester or PP Filter Cartridge

Specifications:

Specifications:

1.Length:5",10",20",30",40"

2.Material: PP,CTO,UDF/GAC,KDF,RESIN,CERAMIC,RO membrane

Type:

1.PP sediment filter cartridge

2.String wound filter cartridge

3.PP pleated filter cartridge

4.Activated carbon filter cartridge

5.Granual activated carbon filter cartridge

6.Post active carbon filter cartridge

7.Resin filter cartridge

8.Ceramic filter cartridge

9.Ultra filter cartridge

10.RO membrane

11.KDF filter cartridge

12. Minerals filter cartridge

Function: Remove the particles, dust,chlorine,taste ,odor and bacteria.

We are a China top manufacturer for all kinds of Water Filter Cartridges: activated carbon UDF/GAC,CTO Filter; PP Melt Blown,String Wound,Pleated Filter; In-line Filter; Refrigerator Filter; Ceramic Filter; Resin Filter; UF Hollow Fiber Filter, Stainless Steel Filter. We are producing and selling 150000-500000 pieces for each type per month.

We also provide original DOW Membrane which we import directly.

Alkaline Water Filter Cartridge

The 4 in 1 Mineral filter has a balanced proportion of vital minerals necessary for human health and proper maintenance and development of the human body.

This mineral filter was designed by top specialists at the military academy in Taiwan.

The beneficial effects of Far Infrared Rays on the human body.

1. Encourages a healthy immune system while providing

protection against harmful viruses and bacteria.

2. Adjusts oxygen levels in the human body.

3. Increases the circulatory systems ability to operate

efficiently.

4. Aids in the elimination of waste from the body.

5. Adjusts and decreases acidic levels in the body.

6. Promotes a healthy nervous system, provides relief

from insomnia, depression, fatigue.

Pleated Filter Cartridges for Membrane Process

Materials: SS304, 316L

Filter media: Sintered web or woven wire cloth

Cartridge Construction:

The process filters have filter media, end and core welded or adhesive jointed.

For welded type, the filter elements are jointed by argon arc welding.

Each layer of the mesh filter is metallurgical bonded.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen